Abstract

In this chapter, a possible outlook into the future is provided. Considering the newest technology on the market in the young research field of AAL (see Chapter 4), and the youngest research projects (see Chapter 5), new possibilities will exist in the future design of buildings. Buildings mainly consist of four walls and a ceiling, with water and electrical supply. However, with increasing demand for assistive technologies, and with an increasing technology readiness level (TRL) [187] for assistive technologies, there will be a time when this new technology approach will fuse with future building design and construction.

In this chapter, a possible outlook into the future is provided. Considering the newest technology on the market in the young research field of AAL (see Chapter 4), and the youngest research projects (see Chapter 5), new possibilities will exist in the future design of buildings. Buildings mainly consist of four walls and a ceiling, with water and electrical supply. However, with increasing demand for assistive technologies, and with an increasing technology readiness level (TRL) [187] for assistive technologies, there will be a time when this new technology approach will fuse with future building design and construction.

6.1 Robotic and Automated Repair, Renovation, and Maintenance in Other Fields

The techniques and procedures used in other fields could be implemented, after an adaptation, in building renovation and AAL topics. In this chapter, the general ideas behind these fields will be explained.

6.1.1 Aircraft Maintenance Repair Overhaul (MRO)

The main commercial passenger aircrafts fly under extreme circumstances. Often, they are constantly in use and they therefore need constant checking, maintenance, and if needed, repairs. The life span of a plane is often 30 years, and during their lifespan many of their parts are repaired. In order to successfully and efficiently achieve this goal, new technologies have been developed.

For instance, at the Lufthansa Technik AG center [188], three main research concepts have been conceived:

Adaptive CNC milling: cost-efficient repair processes for the valuable components;

Robot-based CFRP material repair procedure ready for mobile deployment;

Augmented Reality.

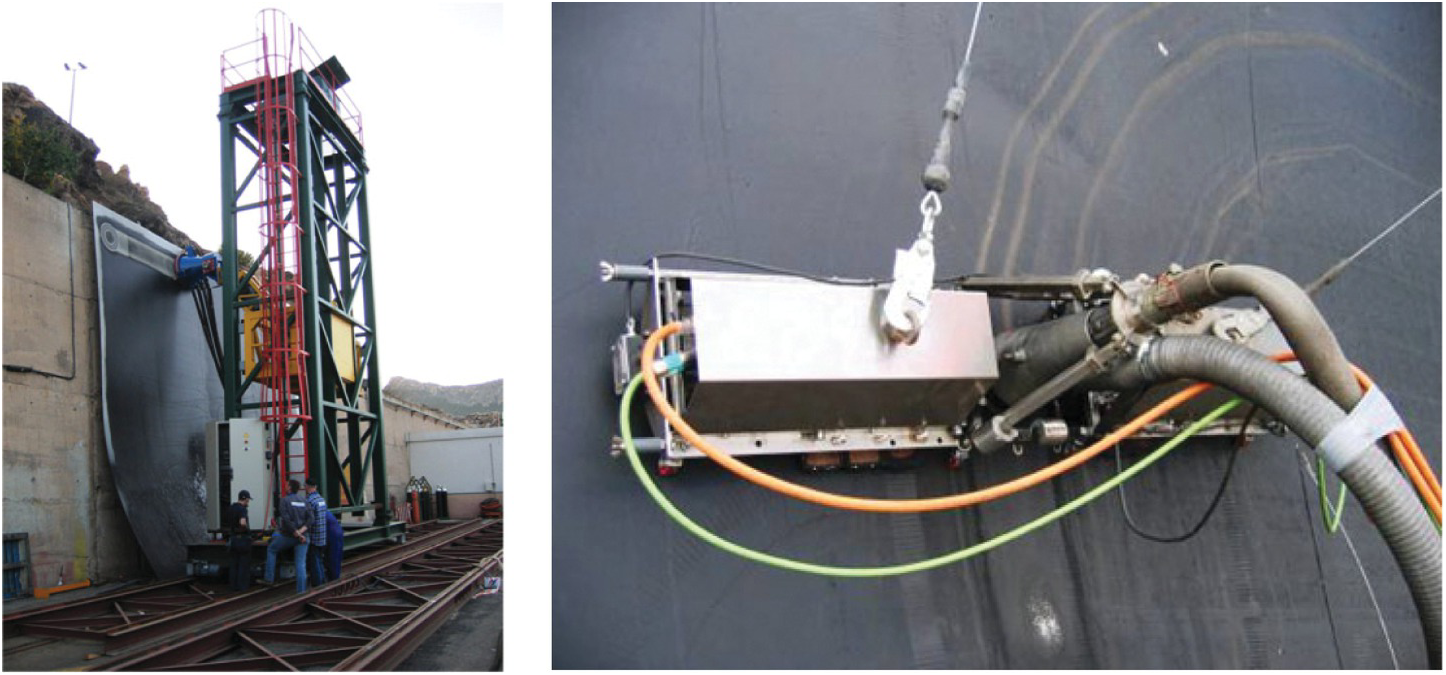

For instance, within the research project name “CAIRE,” a robot placed in a mobile platform was able to recognize and repair damages on the external fuselage of an airplane.

It has to be said that the repair of the aircraft takes place in a hangar: a controlled environment when compared to other buildings. Also, with regard to logistics, it can be said that the main necessary items for the renovation can either be on the workshop or must arrive on time.

Figure 6.1 Automated detection and repair of composite materials.

6.1.2 Automated Repair of Ships

The ship industry is similar to the building industry. Regarding maintenance, several robots have already been developed. As with buildings, two aspects must be considered:

The ship’s hull (body)

The services and mechanical devices.

In regard to the operability of the robots and considering that the repair of the ships is mostly outdoors, there is parallelism with buildings. These concepts are explained further by Fernandez-Andrés et al. [189].

6.1.3 Automated Maintenance, Repair, and Replacement of Oil and Gas Platforms

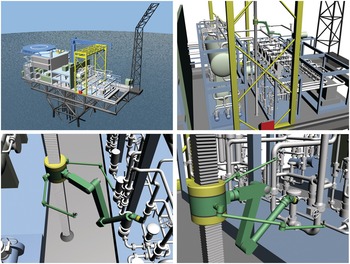

Oil and gas plants normally consist of kilometers of pipes and tubes which are normally within corrosive environments. Especially for off-shore oil and gas platforms, there is a need to replace damaged elements [190].

In these cases, the replaced elements need to be fixed fast enough in order not to stop the extraction of oil or gas.

The possibilities of on-site manufacturing are reduced due to the decreased space of the platform. Therefore, already built-in modules are used. These modules are prefabricated in an on-shore factory.

Figure 6.3 Simulation of off-shore robotic platforms developed by SINTEF (Robotnor).

6.1.4 Medical Implant Technology

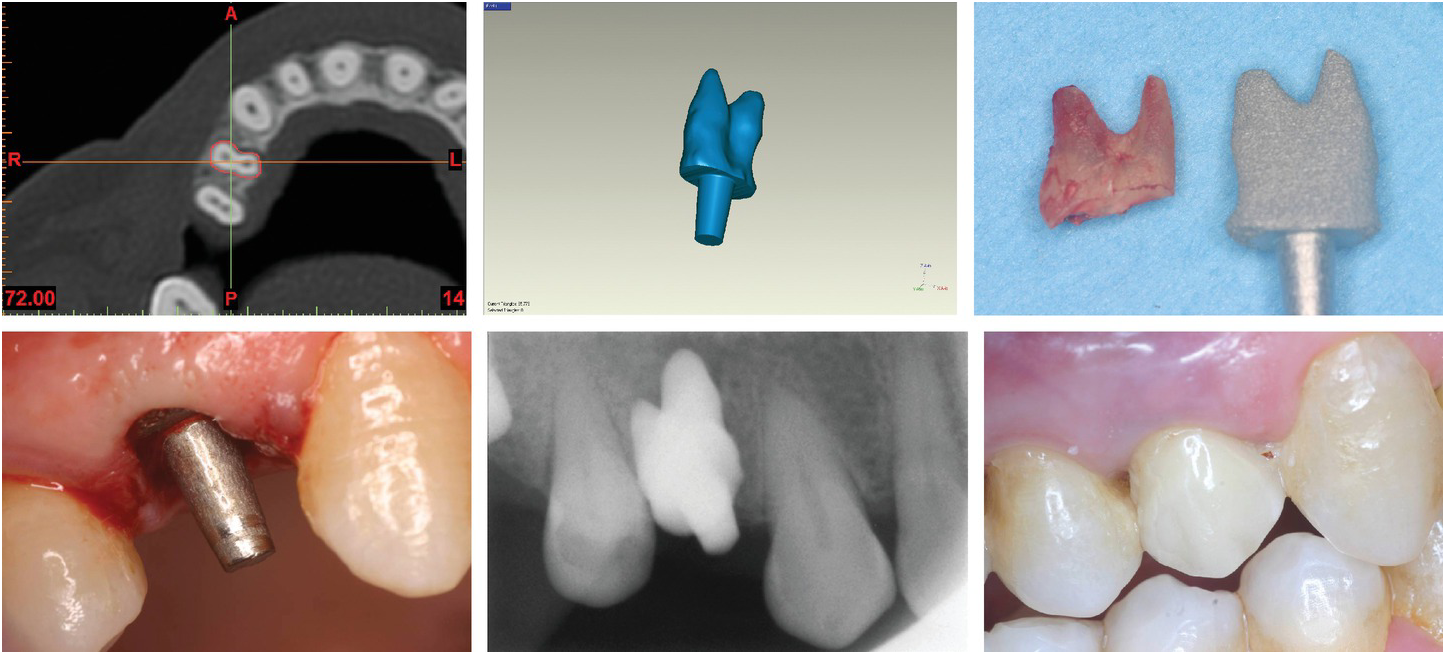

Medical implants are meant to replace or support damaged biological bodies. Somehow, this concept is very much related to building refurbishment, where the unnecessary, defective, or downgraded building elements need to be removed and replaced. Which knowledge can be subtracted from the field of medical implants and reproduced in building refurbishment? In medical implanting, there is an adaptation and fixation of a “standard element” onto a particular geometry. Similar to the case of the buildings, every biological body has a particular and different geometry, and therefore, data acquisition is particularly of high importance. Besides, the implanting technology takes into consideration that the manual positioning of the implant is itself prone to some tolerances. Focusing on dental implants, three parts can be identified: the implant, the abutment, and the crown. Briefly explained, a dental implant process is as follows:

Session 1: First, there is an overall measurement with X-ray or Computed Tomography (CT) scan. This step is done prior to surgery in order to check the current condition of bones and teeth.

Session 2: Once there is an accurate diagnosis and the treatment is defined, the surgery process can start:

First, a hole is carefully made onto the bone, controlling the location with an alignment pin. After that, the implant is inserted into the hole.

Once the implant fixture is inserted into the bone, another geometrical data acquisition is necessary so that the crown can be accurately produced. There are two ways for doing so:

∘ Conventional impression taking with flexible material.

∘ Digital data scanning. This procedure is more accurate than the conventional impression.

Normally in a specialized outsourced workshop, the crown is accurately crafted in specialized workshops.

Session 3: On a final surgery session, the abutment and the crown are inserted.

Recent studies [191] show that there are possibilities to create a bespoke implant that can be placed onto the cavity of the root. This can be done using direct laser metal forming (DLMF) for the manufacturing of the implant, which can also prevent the need of several surgery procedures.

Figure 6.4 Implanting technology. Previous measurement of the teeth, including the root. Create the 3D .stl file for the implant. Insertion of the implant on its required location.

6.1.5 How Can These Concepts Be Adapted onto Building Renovation and Maintenance?

Can these procedures or protocols and technologies be implemented into the building upgrading process? Already, some studies have focused on the possibility of the rearrangement of the final prefabricated module. In our case, however, the question here is if these procedures can be extrapolated to building renovation. In summary, it can be said that in all the analyzed processes, there were some clear emerging concepts. First, there is a measurement of the element to be refurbished. Then, the adjustment of the product and sometimes, a robotic placement. Nevertheless, the robotic installation is a challenge in all cases.

6.2 Future Technological Trends

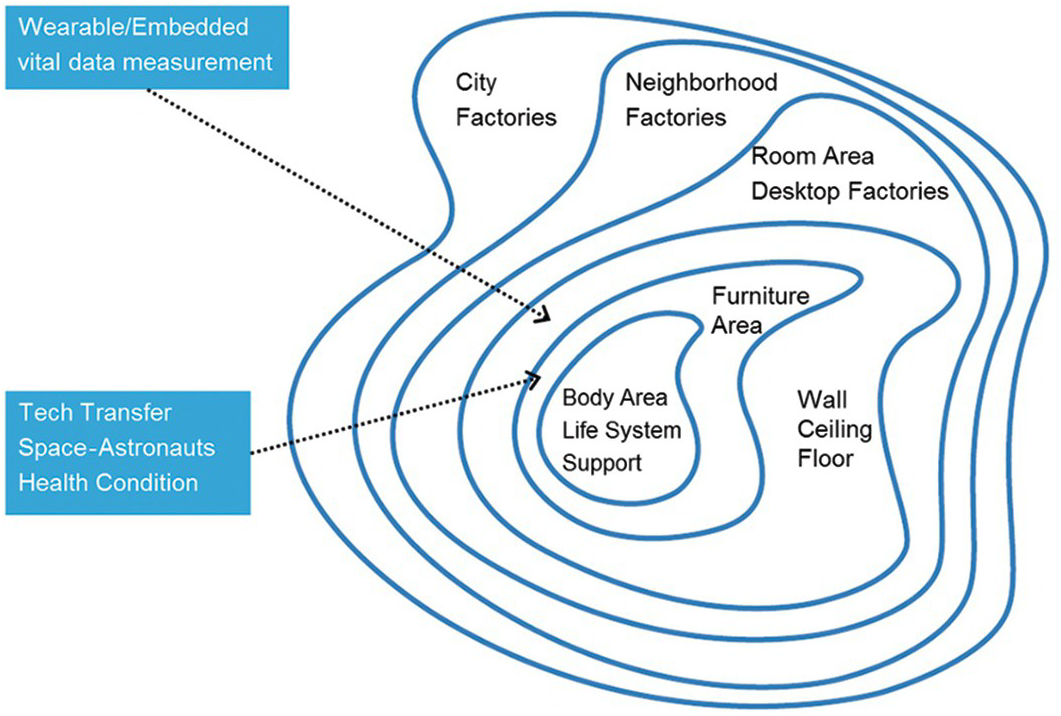

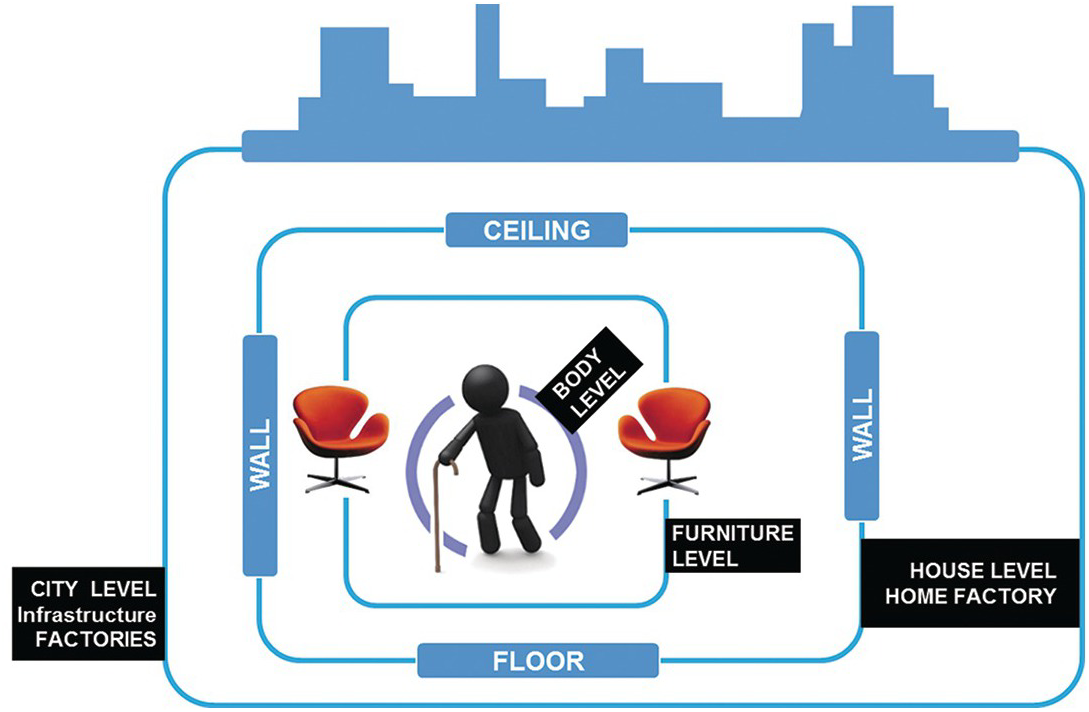

It is expected that the interconnection of things will also affect the AAL area. Wearables and sensors directly attached to the body, as well as intervention options, will be distributed not only into the furniture and home environment, as depicted in Figure 6.5. Also, neighborhoods, public streets, and even factories will become equipped with AAL technology into their environments, as this is motivated by the need to keep a high life quality for the workforce.

Figure 6.5 Expected networking of things in the future, including the current state of technology and ongoing research.

Also, there currently exists no link. An example here is in the car industry; looking back 30 years ago, the car was mainly a mechanical device, but now has assistive systems for safety and comfort unobtrusively embedded in the car, e.g., ABS (antilocking braking system), EBD (electronics brake-force distribution), SRS Air Bags (supplemental restraint system air bags), parking sensors, and cruise control [192]. Furthermore, systems like fatigue detection also exist [193]. The projects as presented in Chapter 5 are aiming to implement the safety and comfort functions through home add-ons; this approach also can be seen in the car industry (e.g., modular navigation systems). Therefore, basic services will probably be implemented in pre-fabricated building modules, resulting in standard assistive functions in apartments or houses of the future.

At the moment, for instance, there are ongoing projects which try to develop settlements that produce their own necessary current. This new development of energy harvesting implemented into new buildings provides also the link to indoor (and, maybe later, outdoor) assistance. For example, the project ZERO-PLUS (“Achieving near Zero and Positive Energy Settlements in Europe using Advanced Energy Technology”) is developing new designs for high energy–performing buildings. In this project, a modular approach which allows the build-up of zero net energy and providing current to buildings by use of highly efficient insulation, heating, and lighting, as well as by innovative energy production technologies (i.e., Linear Fresnel Reflectors, etc.), is considered [194].

Moreover, the aspect of offsite or prefabrication building modules is investigated by research projects like Building Energy Renovation Through Timber Prefabricated Modules (BERTIM). This project is investigating the opportunity to renovate and improve energy performance while at the same time also improving the air quality, aesthetics, and comfort. Therefore, prefabricated modules that include all necessary water pipes and current wires will be produced. Here, the interfacing of these modules by specially designed connectors as described in [139] is one of the main challenges being solved as part of this project.

Fusing these projects with AAL, e.g., by implementing the assistive AAL technology for safety (e.g., fall detection, as mentioned in Chapter 5), or comfort (assistance in getting clothes on, etc., as described in Chapter 5), would increase the aesthetic and life quality at the same time. Additionally, connecting these modules to plug-and-play modular interfaces (e.g., by using similar connectors as described in [139]) and to a power supply (e.g., a solar cell), which is used in the building (as proposed in ZERO PLUS), can be seen as topics for future research interests of high tech architecture and civil engineers.

6.3 Future Research/Visions for AAL and Construction Automation

The possibilities of AAL technology are not limited to prefabricated modules (e.g., furniture, walls, ceiling, etc., see Figure 6.6), which embed all service functions in modular power generating prefabricated apartment and house modules as described in Chapter 1. Wearables can improve safety on construction sites by predicting outcomes. For example, the EVA suits for space walks are equipped with some wearables (see Section 1.1), which aim to measure the stress levels of astronauts.

Stress levels are of interest because high stress leads to mistakes. Additionally, under prolonged stress, health conditions suffer. Attention is important as a lot of accidents happen when people are distracted. For example, motormen (e.g., in German ICE trains) have to give permanent feedback of their attention to their work, by using a pedal on the chair ground. Through arrhythmic pressure, the motorman gives the train feedback that he is awake and focused. If the motorman stops, or becomes too arrhythmical in the feedback, the train knows that the motorman is not awake or focused and will stop the ride. Following the example of the trains, AAL systems can also be used in the construction site to determine the attention and conscious of the workers so as to prevent accidents.

AAL technology, which also focuses on scanning and measuring health parameters like pulse, blood pressure, breath, etc., can help to retrieve similar information from construction workers, which would allow an intervention before an accident happens. Additionally, determination of whether the work conditions and behavior are appropriate to the health condition (ergonomically correct lifting of objects, etc.) can be proved. The ability of a worker can be maintained or kept. This is very important because the number of available workers is decreasing as the population ages (see Section 1.2). Being able to work at construction sites in old age is an exception to what is typical. However, by using AAL technology at the workplaces, especially on such dangerous places like construction sites, these exceptions might change.

In addition, it sounds strange to combine two totally different fields; AAL is a highly interdisciplinary research area while civil engineering and architecture are the exact opposite. Nevertheless, fusing two different fields always results in new possibilities and new interdisciplinary solutions, which will improve the quality of life and work. For example, mechatronics is the fusion of electronics and mechanics. Later on, medicine and mechatronics were fused into medical engineering. The fusion of these three different engineering fields resulted in a myriad of medical devices. Robotics and AAL are a multidisciplinary fusion of even more scientific fields (electrotechnology, mechanics, informatics, medicine, regulation technology, social sciences, etc.) and its promises are already showing great potential.

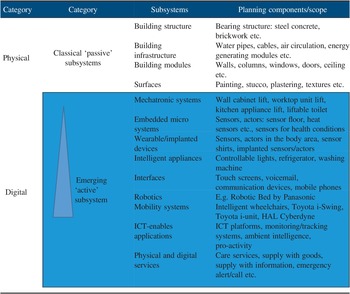

However, the possibilities created by fusing AAL with civil engineering and high-tech architecture is at the moment unpredictable but allows for high expectations for cities of the future. Table 6.1 gathers all the robotic ambience categories and systems mentioned in this book.