The amount of energy available from the Sun is almost unimaginable. One hour of sunlight falling on the earth has enough energy to power the entire earth for a year. If engineers can capture 1 percent of this energy, the energy to power the earth for a year could be captured in 100 hours. Assuming 8 hours per day collection time, it would take 12.5 days of captured solar energy to power the earth. Even if only one-tenth of this amount can be captured, it would only take 125 days of captured solar energy to power the earth. Solar energy also drives the winds and ocean currents. A month’s worth of energy captured from wind could power the earth. There is also the geothermal energy of the earth itself. As fossil fuels get more expensive and harder to find, alternative fuels will become more and more affordable. Remember that coal replaced wood as society’s fuel as the industrial revolution was beginning partially because wood became scarce (Gore 2009, 52–57).

Electricity can be generated from sunlight using mirrors to concentrate solar energy to heat a fluid, which then creates steam to turn a turbine to produce electricity. Electricity can also be generated directly from photovoltaic panels.

Concentrated solar thermal energy plants are large utility owned installations. There are three varieties. One has a large array of two axis tracking mirrors that reflect solar energy onto a receiver mounted on a tower (Figure 32.1). The high temperature fluid is then used to create steam to drive electric generators (Gore 2009, 64). The Ivanpah Valley, California solar tower power plant has 173,500 computer controlled mirrors focusing solar energy on a receiver at the top of a 46 story tower. Water is heated to 1,000 degrees Fahrenheit, creating steam to generate electricity. Enough electricity will be generated to power 140,000 homes (Bernstein 2014). Another method of concentrating solar energy is an array of linear parabolic reflectors that focus the Sun’s energy on a pipe filled with a specially designed fluid. This heat is then used to generate steam in a heat exchanger. The steam is used to generate electricity. The parabolic trough can be a smooth parabolic mirror or it can be made from many flat mirrors arranged in a parabolic shape. The third method involves a parabolic dish mirror that tracks the sun focusing solar heat on a receiver attached to the mirror dish. The heat generated is used by a Stirling Engine to generate electricity (Gore 2009, 64).

FIGURE 32.1 A solar tower power plant in Daggett, California.

Source: Wikimedia Commons, Attribution-Share Alike 3.0, Photo by Kjkolb 2003.

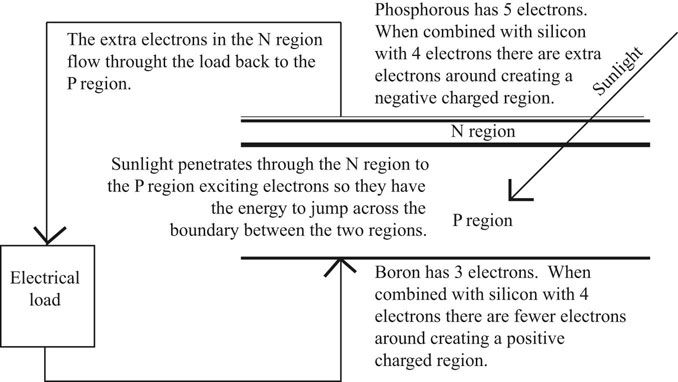

FIGURE 32.2 Photovoltaic panels produce electricity directly from the Sun by exciting electrons in the photovoltaic material.

Traditional photovoltaic panels are made from silicon (Figure 32.2). A thin top layer has a small amount of phosphorous in it, which supplies extra electrons. Silicon has four valance electrons. Phosphorous has five valance electrons. A thicker lower layer has a little boron in the silicon. Boron has three valance electrons. Thus the upper level has a slight negative charge and the lower level has a slight positive charge. Because of the slight deficit of electrons in the lower level, the electrons have more room to move around and have slightly more energy than the electrons in the upper level. Where the two layers join together there is a resistance to the passing of electrons. Sunlight comes through the thin upper layer and excites the electrons in the lower layer enough so they can jump across the boundary between the two layers. This creates an excess charge in the upper layer, which is collected and sent through circuits to provide electricity to a use (Strong and Scheller 1993, 15–18). Photovoltaic panels produce direct current. Most household and com mercial appliances and the utility grid use alternating current; thus, a solid state controller is necessary to produce alternating current.

Photovoltaic panels lend themselves to distributed use. They can be mounted in small, medium, or large arrays almost anywhere (Gore 2009, 68). When a utility grid is available the most straightforward method of storing excess electricity production during the day is to send the extra electricity back into the electric grid. If the utility grid is not available, then batteries are necessary to store electricity generated during the day for use at night or during cloudy weather. Batteries are sized by determining the amp hours they need to deliver. Amp hours are calculated by dividing the watt hours of energy required by the building per day by the voltage of the system and battery bank. Often this is 24 volts. The amp hours per day are multiplied by the number of days of storage required and by a 1.2 discharge factor since batteries can only discharge 80 percent of their total charge (Grondzik et al. 2010, 1342).

Another form of photovoltaic panel is thin film amorphous silicon. These panels are less expensive and less efficient. Traditional silicon cell panels are from 10 to 15 percent efficient depending on their temperature. Amorphous silicon panels are from 5 to 7 percent efficient also depending on temperature. The efficiency is highest when the panels are cool, 50 to 60 degrees Fahrenheit, and least efficient when they are in the range of 110 to 120 degrees Fahrenheit (Humm and Toggweiler 1993, 99). Thus, it is important to mount photovoltaic panels so that they can ventilate away heat. It is also important to mount photovoltaic panels so that they are not shadowed at all during most of the day. Even a small amount of shadowing drastically reduces output.

Photovoltaic panels of either type come with a voltage and a current rating. Connecting the panels in series adds individual panels’ voltages together so that it increases the voltage of the array of panels. Connecting the panels in parallel adds the individual panel’s current together so that it increases the current output of the array of panels. Most photovoltaic arrays are connected in a combination of parallel and series connections to provide the voltage and current required (Figure 32.3).

FIGURE 32.3 Nellis Air Force Base 15 megawatt photovoltaic power plant.

Source: US Air Force photo, public domain.

The National Renewable Energy Laboratory (NREL) provides a website (www.nrel.gov.rredc/pvwatts) that calculates the power output of a solar array anywhere in the world. The array size is inputted in kilowatts. Each photovoltaic panel is rated for voltage and amps. (Watts = volts × amps.) Multiplying the watts produced by a single panel by the number of panels will give the watts produced by the array. A kilowatt is 1,000 watts. The tilt and azimuth of the array can also be inputted. A tilt equal to the latitude provides maximum power over the entire year. A lower angle will provide more power in summer, and a higher angle will provide more power in winter. There is a version 1 and a version 2 of the program. They both perform the same calculation.

Wind is created by uneven heating, which causes air to flow from hotter areas to colder areas. Wind is a widespread resource with the capacity to provide vast supplies of electricity. History credits Persia with the first windmills, which then spread to China. Windmill technology came to Europe with the crusaders where it found widespread use to pump water, grind grain, and saw wood. Until coal and the steam engine replaced them, windmills were an important technology used to create turning motion (Gore 2009, 86).

Modern windmills have three blades designed like airplane wings to generate efficient lift as the wind blows over the blade. The blades are typically 100 feet long and are mounted on 300 foot high towers. They each produce an average of 1.5 megawatts of electricity, enough for 400 homes. These large windmills are generally located in groups owned by utility companies and connected to the utility grid. Windmills are currently the least expensive source of solar energy (Gore 2009, 80).

A wind turbine cannot take all the kinetic energy out of the wind since the wind flows through and past the turbine. The maximum theoretical power extraction is 59 percent. This is Betz’s law, developed through calculations on an ideal wind turbine by Albert Betz, a German physicist in 1916. Real wind turbines have friction losses that reduce their output to about 75 percent of the maximum possible output. Thus a well-designed wind turbine can expect to harvest 44 percent of the kinetic energy available from the wind (Grogg 2005, 7–10). The wind power density (WPD) is a measure of the average annual power per square meter of area the windmill blades swing through. The wind power density increases with height. The National Renewable Energy Laboratory (NREL) publishes maps of the United States classifying wind sites. The ratings range from Class-1 through Class-6 with Class-6 having the highest winds. Commercial wind farms are generally located on sites with high wind power densities (NREL, Wind Resources 2014).

Most commercial wind turbines are horizontal axis machines. Wind turbines can have their blades upwind of the tower or downwind of the tower. When the blades are downwind of the tower the wind naturally keeps the blades perpendicular to the wind, but the tower then is upwind of the blades, which creates turbulence in the air stream which reduces power output. This turbulence is avoided if the blades are kept upwind of the tower. To keep the blades upwind, aimed into the wind, large turbines use a wind sensor connected to a motor. Large commercial wind turbines rotate at 30 to 60 revolutions per minute. A gear box is used to increase the rotational speed of the electrical generator, which is a coil of wires rotating in a magnetic field. The power created needs to be generated at or converted by solid state circuits to alternating current at 60 cycles per second to interface with the electrical grid. All wind turbines have design features to keep them safe in very high winds. The individual blades can be rotated into the wind and breaks can stop or slow down the blades. These large wind turbines are generally grouped in wind farms (EERE, Wind Turbine 2014).

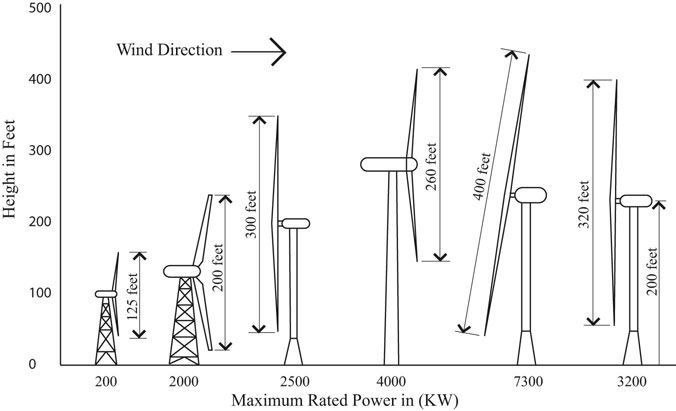

Utility scale wind turbines range from 1.5 to 7.5 MW at the high end, and from 500 kW to 1.5 MW at the lower end (Figure 32.4). They are usually grouped in wind farms, and require environmental and civic coordination along with aviation lighting. Commercial scale wind turbines ranging from 10 kW to 250 kW are suited to campuses, businesses, or communities. The mounting is not as high but still requires special permits. Residential scale wind turbines range from 2 kW to 10 kW. They can provide a healthy percentage of residential energy use, but careful consideration of location is necessary since the towers are not high and surrounding buildings create turbulence (EERE, What is Wind Power 2014).

There is a misconception that windmills kill large numbers of birds. Windmills cause the death of about 30,000 birds per year compared to 550 million killed by tall buildings, 130 million killed by power lines, 100 million killed by cats, and 80 million killed by cars (Gore 2009, 84).

FIGURE 32.4 Wind turbines of varying size and capacity.

Source: NASA.

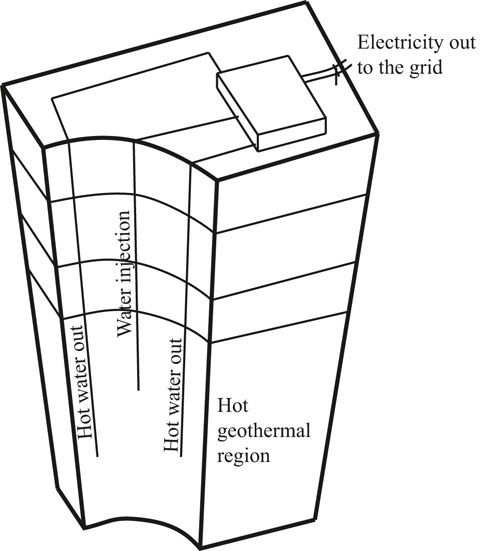

FIGURE 32.5 Geothermal electricity generation.

Wind energy and concentrated solar thermal have the problem of intermittent generation of electricity. Currently there is no good method of storing electricity. It needs to be generated as needed. The current electric grids do not respond well to intermittent sources when the amount of intermittent electricity exceeds 20 percent. The country needs to develop smart grids that can accept more intermittent power and can span across the country in order to integrate solar and wind power (Gore 2009, 91).

Geothermal power is the use of hot underground rock to heat water that creates steam to turn turbines that produce electricity (Figure 32.5). Numerous estimates of the potential of geothermal power suggest great promise. Geothermal power is also continuous, unlike the intermittent nature of solar and wind. But like solar and wind, geothermal creates electricity without any carbon dioxide emissions. Most current geothermal electricity production is located where there is geothermal heated water near the surface, which gives the impression that geothermal is not widely available. However, the ring of fire that surrounds the Pacific Ocean is ripe for geothermal development. There is also a hot zone that runs along the Mediterranean Sea and then across the upper Middle East into Iran, and another that extends down the red sea and along the riff valley of Africa. In addition to these hot areas related to plate movements, there are hot spots distributed around the earth. The Hawaiian Islands were created by one of these hot spots. Yellowstone is another example of a hot spot (Gore 2009, 94–95).

Geothermal power plants use steam created from hot water or hot rocks found a few miles below the surface. Geothermal plants come in three varieties: dry steam, flash steam, and binary cycle. Dry steam geothermal power plants have access to steam that comes from the well to the steam turbine, which turns the generator to create electricity. Access to underground steam of this type in the United States is limited to The Geysers in Northern California and Yellowstone National Park. The electrical generation at the Geysers provides a little over half the electrical power for the north coast of California. Flash steam plants are located where there is hot water at 360 degrees Fahrenheit or hotter and under pressure. A well brings the water to the surface where lower pressure causes steam to form. The steam is used to power turbines creating electricity. The excess water and condensed steam is put back into the ground creating a sustainable closed loop. This is the most common geothermal power plant. A variation on this process is used when the underground water is slightly cooler. The hot water is drawn up the well where it is run through a heat exchanger to boil a secondary fluid with a lower boiling point than water. The resulting steam is used to drive the turbines. The condensed secondary fluid is then recirculated back to the heat exchanger to be boiled again (NREL, Geothermal 2014). Where there is no water underground but there is hot rock, fracking can create permeable rock at the depth where there is enough geothermal heat, rock at 300°F to 400°F, to heat water pumped down and out of the hot zone. About 5 percent of the water is lost during this process (Gore 2009, 100). The United States Geological Survey estimates that there is enough geothermal potential in the western United States to supply close to half the electrical power needs of the country (Hendley 2008, 3).

A heat pump takes heat out of a cold source and then, using electrical energy, upgrades the quality and temperature of the heat so that it can be used to heat an interior space. There is a working fluid that can be compressed into a high temperature high pressure vapor. The high temperature vapor gives off heat, as it condenses to a liquid, to an air handler, which then delivers the heat to the interior spaces. The high pressure liquid then goes through an expansion valve that creates a low pressure, low temperature stream of liquid droplets. This low pressure liquid is colder than the outside air or the ground, so heat flows into the liquid, evaporating it, creating a low pressure vapor that is then compressed to create the high pressure vapor. The cycle thus pumps heat out of a colder source, the air or the ground, and then uses electricity to upgrade the temperature of the working fluid, by compressing it, so that the heat can flow into the building. Cooling is achieved by a valve that switches the hot condenser coil to the outside and the cool evaporator coil to the inside. Individual houses and modest commercial buildings can take advantage of the stable temperature of the earth through the use of ground source heat pumps. At 10 feet down, the earth temperature is fairly stable and near the average temperature for the year at that location. The result is ground temperatures of 50 to 60 degrees Fahrenheit. A ground source heat pump takes heat out of the ground to heat a building in winter and puts heat into the ground while cooling the building in summer. A yearly heat flow balance is maintained. The ground is warmer than the air in winter and cooler than the air in summer, so a ground source heat pump’s coefficient of performance (COP) is higher than an air source heat pump’s COP. The temperature difference the ground source heat pump works against is smaller than the temperature difference the air source heat pump works against. Moist ground is better than dry ground because moist ground conducts heat better. Finally, these systems are often called geothermal heat pumps, which is an incorrect use of the term geothermal. Ground source heat pump is a more descriptively correct term.

Biomass energy can be produced from trees, corn, sugarcane, switchgrass, mascanthus, and agricultural waste. These organic materials can be used to produce thermal energy for heating or the production of electricity. They can also be fermented into liquid fuels for use in transportation (Gore 2009, 114).

The use of biomass to generate energy is as old as fire. Burning wood is still the largest use of biomass. Burning biomass produces carbon dioxide and water just like burning fossil fuels. The difference is that the carbon in the biomass was recently taken out of the atmosphere. When it is burned the carbon dioxide is returned to the atmosphere. There is no net gain or loss of carbon dioxide in the atmosphere other than the energy it took to plant and harvest the biomass. Biomass crops are best grown on already cleared land since clearing forest land creates a carbon debt that takes decades to repay. Burning fossil fuels adds carbon dioxide into the atmosphere that was taken out of the atmosphere long, long ago; thus, burning fossil fuels increases the carbon dioxide in the current atmosphere (NREL, Biomass 2013).

A good example of biomass use is the production of ethanol from sugarcane in Brazil, which began in the mid-1970s. The sugarcane is grown on about 2 percent of Brazil’s arable land. Sugarcane produces 650 gallons of ethanol per acre. Sugarcane works well in the tropical environment of Brazil but does not translate well to the northern climate of the United States. Corn grows well in the United States, but it is a food crop, and it yields less energy per acre than sugarcane. In addition, if the entire United States corn crop was made into ethanol it would only supply 13 percent of transportation fuel needs (Gore 2009, 118–122).

A more promising approach to biomass is the use of tall grasses like switch grass, fast growing trees, and left over waste from food crops. All these non-food crops have high cellulose content, which is good for the production of ethanol, but cellulose resists the bacteria of fermentation. As a result enzymes are being tested with a hydrolyzing steam process to break the cellulose down so it can be fermented into ethanol. Switch grass has the potential of producing 1,000 gallons per acre (Gore 2009, 122–124).

Ethanol can also be made in a gasification process where high temperatures combined with low oxygen create synthesis gas (hydrogen and carbon monoxide). This gas can then be chemically modified to create ethanol. The National Renewable Energy Lab (NREL) is exploring the use of algae to create the biomass input for biodiesel, gasoline, and jet fuel. Algae produces biomass at a high rate (NREL, Biomass 2013).

Biomass can be used to generate electricity. Most bioelectricity plants directly burn the biomaterial to create steam that is used to turn turbines to generate electricity. Cogeneration, using the waste heat from the electricity generation to heat buildings or do other jobs, greatly increases the overall efficiency of the process. Paper mills are the largest users of this form of electricity generation. Co-firing is the mixing of biomass with conventional fossil fuels, such as coal. Synthesis gas can be used like natural gas in a gas turbine driven electrical generation system. Biomass can be made into a liquid oil through a high temperature process without oxygen. The oil can then be burned to generate electricity. Landfills contain organic materials that decompose producing methane. The methane escapes into the atmosphere, which adds to the greenhouse effect. Methane is a much more potent greenhouse gas than carbon dioxide. Wells can be drilled into landfills to capture the methane to be used to generate electricity. This process keeps the methane out of the atmosphere and generates electricity. Methane can also be produced directly from organic matter through an anaerobic process. This process can scale down to small digesters producing methane to be used in generators providing electrical power to remote sites (NREL, Biopower 2013).

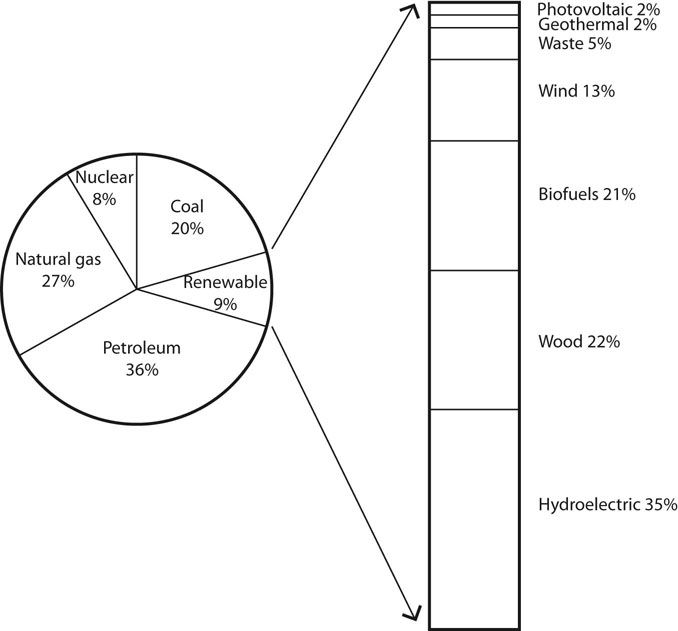

FIGURE 32.6 Renewable energy as a percent of total United States energy use.

Source: United States Energy Information Administration, Annual Energy Review 2011. www.eia.gov/are

Plastics and a wide range of products are made from fossil fuels. Fossil fuels are carbon and hydrogen. Biofuels are carbohydrates made from carbon, hydrogen, and oxygen. Both materials can be broken down into simpler chemicals that then can be recombined to create plastics and other products. The products made from biomass include plastics, glues, artificial sweeteners, textiles, and synthetic fabrics, wood adhesives, molded plastic, and foam insulation (NREL, Bioproducts 2013). Calvin Klein makes a sport coat from modal. Modal is a synthetic fiber made from cellulose from beech trees.

Biomass use is in a very early stage of development. If one considers how food crops such as wheat and corn were transformed from wild grasses with small amounts of edible material to their current state, it is certainly in the realm of possibility that biofuels from biomass could also make a dramatic change.

Currently renewable energy sources provide 9 percent of the energy use of the United States. With peak oil production projected to happen soon, there is an urgent need to invest in renewable energy technology development.