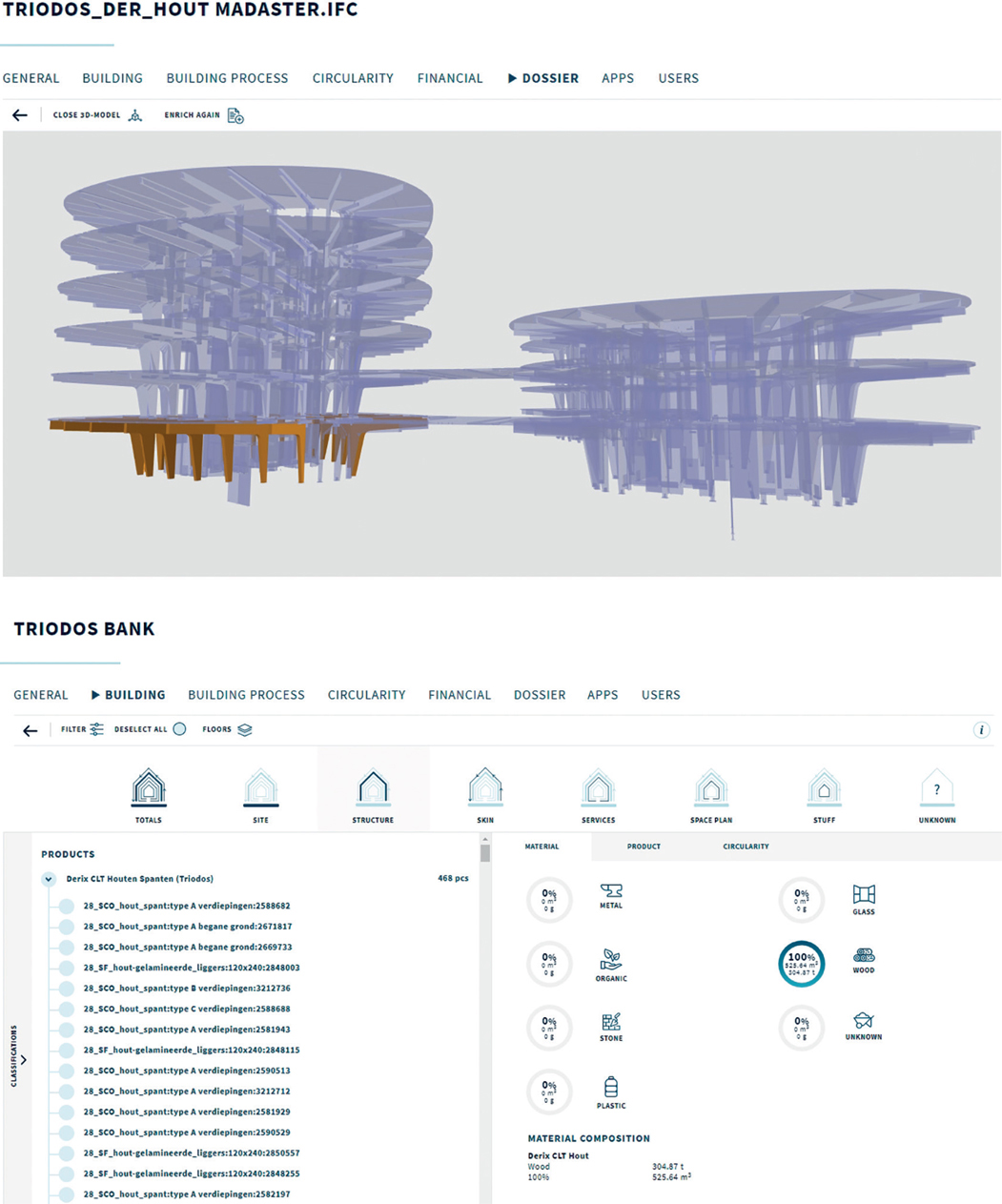

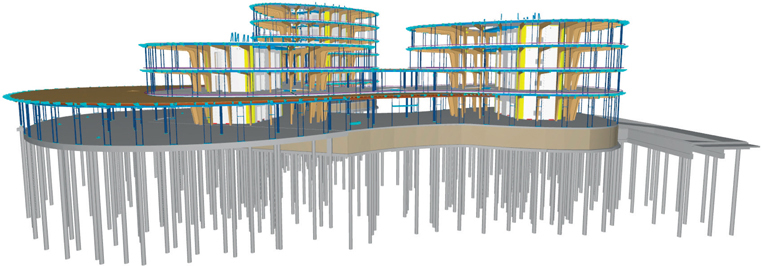

FIG 20.0 (chapter opener) A predominately timber structure is an appropriate response to the bank’s corporate philosophy as well as the woodland setting. Areas of interest: Full timber hybrid for new office; Circular economy approach; Fully demountable design; Use of materials passport. Commissioned by Triodos Bank, this new office building embodies the clear investment values of the occupying organisation, creating a 21st century workplace with a long-term view of resource ownership and value. Three compact towers are connected by a shared plinth at lower levels. Above a concrete basement, cores, floor and roof elements are CLT with sculptural glulam beams and columns radiating from around the cores at the centre of the upper floor pop-ups. FIG 20.1 BIM view illustrating central cores and plinth below upper floor workspaces. The structure above ground floor slab is predominantly CLT with glulam columns and sculptural beams. Mostly glazed externally with a flush curtain wall, a priority was creating a high-quality internal environment. A limited palette of materials is used alongside exposed timber elements with glulam columns and beams and CLT expressed to cores where vertical CLT panels form lift shafts anchoring other elements and to soffits, with screening from decorative timber elements and soffit-mounted service panels. CLT was also used for stairs and roof slabs. Beyond the structural solutions, all CLT panels and major materials used were considered in terms of design for disassembly and maximum value reuse from the outset. This is a bank building that is also a materials bank and a very deliberate investment for the future: a great example of a low-impact building that reflects circular economy principles as well as any built to date. FIG 20.2 CLT floors are partially masked by timber ceiling level ribs that allow access to chilled/radiant panels and services fed from risers within the CLT cores beyond. Minimising the carbon footprint of the building was a concern for the project team and as such, concrete use was limited to basement areas due to the proximity of ground water – it is never good practice to use CLT below ground level. Elsewhere, structural elements are virtually all mass timber. Glulam beams span from central cores creating generous floor heights and emphasising a free-form facade with full flexibility for glazing, shading and opening lights where required, maximising daylight penetration and visual connection to the surrounding woodland setting. FIG 20.3 Four storey height panels were used to create stability cores and vertical shafts. FIG 20.4 Once lifted into position, vertical panels require propping only until neighbouring panels are secured. FIG 20.5 CLT shafts are typically better aligned than those made of other materials due to extremely tight tolerances and allow rapid fixing of lift installations and services. From the outset, a collaborative approach was adopted to maximise potential gains and best address technical issues. Having previously worked for the same client, the architect and many of the team were brought together at the outset with construction advisors, the contractor and its subcontractors. This has been acknowledged as a key factor in delivering what is a ground-breaking building, in terms of initial construction, timber performance and future potential for demountability and maximum-value materials re-use. FIG 20.6 CLT stability core and shafts with glulam columns and beams before the installation of first floor CLT slabs. All timber fixings were designed to be demountable and recorded (down to the last screw) to maximise future value and potential reuse of elements and materials. Beyond physical aspects considered, data around CLT and other key materials use was considered with every element identified and documented. Information and key characteristics are recorded within a building specific materials passport for future reference. This fundamentally changes the way the building can be valued and by adding clarity and certainty to records, better ensures that elements stand the best chance of being reused at end of first life with minimal loss of value (rather than rather than downgraded or down-cycled). RAU Architects were instrumental in establishing the Madaster database, a commercial materials passport platform that aims to ‘eliminate waste by providing materials with an identity’.1 Using a total of 165,312 screws, structural connections including all fixing of CLT was undertaken using dry processes to maximise the potential for disassembly and subsequent highest value reuse. During first use, such an approach facilitates maximum flexibility by enabling elements to be relatively easily moved/taken away/replaced where required and the hoped-for reuse of individual elements on other sites (second and subsequent use) is made more attractive by the relative light weight of the timber elements used. If dismantled, elements may be handled relatively easily with the CLT being around 20% of the weight of concrete alternative elements. FIG 20.7 Extracts from the buildings materials passport, held within the Madaster database. This platform was developed independently by the architects and records key data about the materials, components and products within a building taken from BIM.

CASE STUDY

TRIODOS BANK OFFICE BUILDING, DRIESBERGEN-RIJSENBURG, THE NETHERLANDS

Project name:

Triodos Bank Office Building

Location (including local authority):

Driebergen-Rijsenburg, The Netherlands

Sector/type:

Office (new build)

Year completed:

2019

Area of building (GIA):

13,000m2

Volume of CLT (m3):

2,623m3

Overall construction cost (million):

Not disclosed

Total height of building:

25m

Client(s):

Triodos Bank

Architect:

RAU Architects

Main contractor:

J.P. van Eesteren

QS:

PMP Consultants

Structural engineers:

Aronsohn (Rotterdam), Luning (Arnhem)

Timber engineer:

Aronsohn (Rotterdam), Luning (Arnhem)

CLT contractor:

J.P. van Eesteren, Derix

CLT manufacturer:

Derix, Groot Vroomshoop

PROJECT SUMMARY

PROJECT AMBITIONS

EARLY COLLABORATION

CIRCULAR ECONOMY APPROACH

The building as a materials bank

Design for reuse