Heating and cooling in commercial buildings involves multiple zones with differing characteristics. Zones can have different schedules, temperature set points, air quality needs, internal heat, and need for heating, cooling, and/or ventilation. In addition there are interior and exterior zones. For example, outside air requirements are higher in an auditorium than in an office area. To minimize energy use these two uses should have separate air handlers. The following list of questions used as a series of filters can aid the partition of a building’s uses into similar thermal zones.

• Do areas have similar schedules of use?

• Do areas have similar temperature set points?

• Do areas have similar ventilation and air quality?

• Do areas have similar internal heat generation?

• Do areas have similar needs for heating, cooling, and ventilation?

As an example consider a modest art gallery building with art galleries, art storage, exhibit preparation, administrative offices, and circulation. Similar schedules divide the uses into two groups. Group one, the galleries, art storage, and exhibit preparation, needs 24 hour thermal control because of the art. Group two, the administrative offices and the circulation, only needs about 10 hours of HVAC operation while people are in the building. Similar temperature set points do not change the groupings because they all will have similar set points. Similar ventilation and air quality creates some new groupings. The galleries, administrative offices, and circulation need ventilation amounts for people. The art storage area does not need as much outside air ventilation because there are very few people involved. The exhibit preparation will require high ventilation rates and separate exhaust so that dust and fumes are not spread around the rest of the building. Similar internal heat, and similar need for heating, cooling, and ventilation, do not create any new groupings. The final partition of the building into zones with similar HVAC needs is as follows. The galleries need 24 hour HVAC with possible humidity as well as temperature control. The art storage also needs 24 hour HVAC but as a storage space considerably less outside air ventilation will be required. The exhibit preparation requires high ventilation rates and separate exhaust and, when delicate art is in the space, 24 hour operation. The administrative offices and the general circulation only need to operate about 10 hours per day when people are present in the building. The result is that the building should have a minimum of four air handlers, one for each distinct thermal zone. Matching air handlers to thermal needs allows the building to be tuned for minimum energy use.

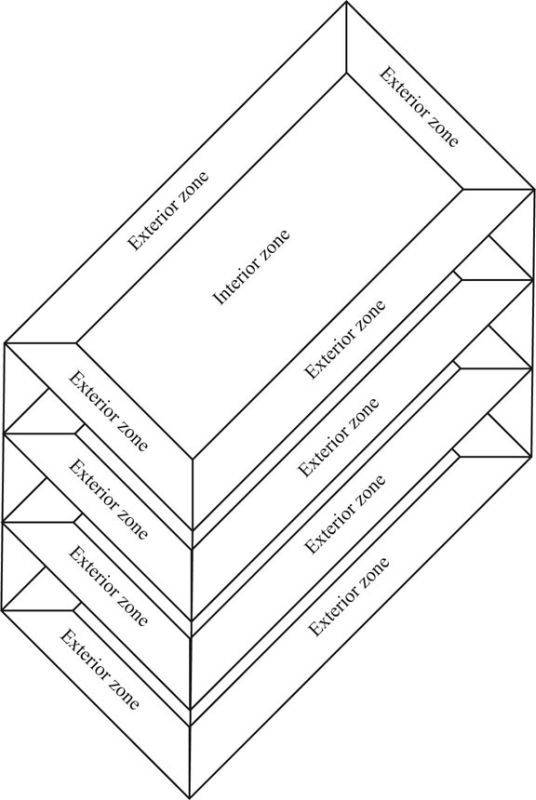

Commercial buildings also have exterior and interior zones (Figure 23.1). The exterior zones are the exterior offices, or the 15 to 20 feet of an open plan building closest to the exterior windows. These exterior zones face different directions. In a cardinal oriented building the exterior zones face north, south, east, and west. These zones will have different thermal needs at different times of day and in different seasons of the year. In summer high cooling needs will move around the exterior zones, starting with the east followed by the south and then the west. In winter the need is mostly heating but on a clear sunny day the south zone may need cooling. The energy use of exterior zones is driven by exterior climate conditions and thus insulated walls and high quality glass are important. The interior zones of a building need cooling all year long. Consider the thermal situation of an interior zone on a middle floor of a building. It is surrounded by conditioned space above and below by other floors and all around by the exterior zones. There is no path for heat loss to the exterior no matter how cold it is outside. However, there are plenty of heat gains from people, lights, computers, printers, and copy machines. This internal heat needs to be conditioned away with the introduction of cool air to these internal spaces all year long. Because of the different loads on exterior zones and interior zones, it is essential that exterior and interior zones be treated as separate thermal zones with separate air handlers.

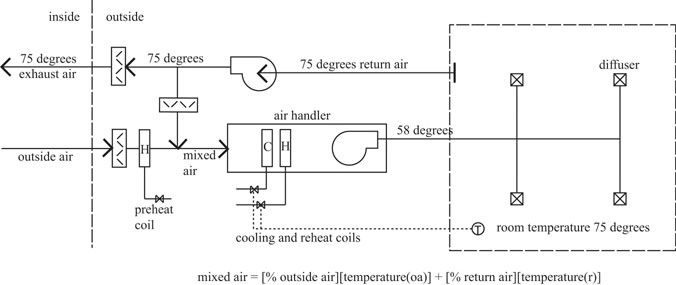

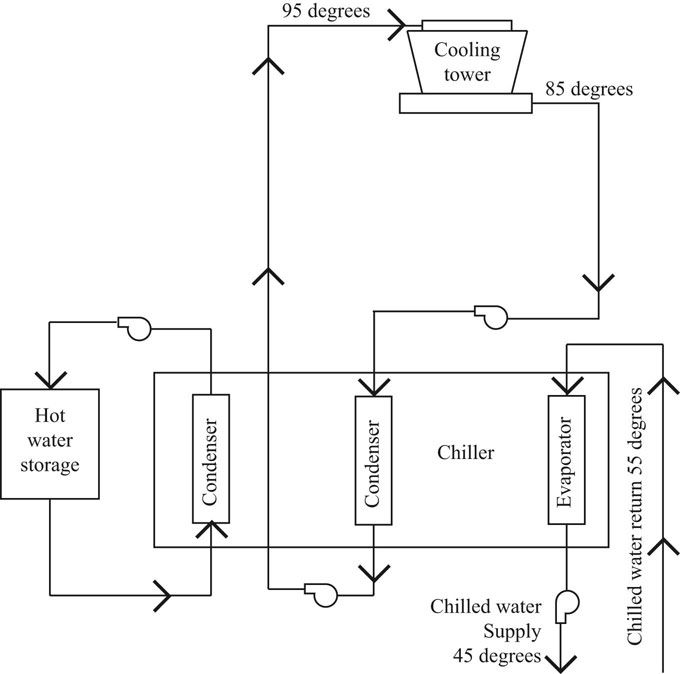

Air handlers condition the air delivered to a space through the use of heating and cooling coils (Figure 23.2). The hot water for the heating coils comes from a boiler that will require a flue to vent exhaust gases to the outside. Chilled water comes from a chiller that requires a cooling tower located outside the building to reject the heat, taken out of the chilled water, to the outside air. There is usually one mechanical room location for the boiler and chiller and their accompanying pumps. As buildings get larger, there is usually more than one boiler and chiller for two reasons. The first reason is to avoid interruption of service when a boiler or chiller needs maintenance. The second reason is energy efficiency. Most of the year buildings operate at considerably less than their peak heating and cooling needs. Boilers and chillers run more efficiently at full output so having a sequence of boilers and chillers to turn on as the load increases is more efficient than having one large boiler and/or chiller running at part load.

FIGURE 23.1 Interior and exterior zones.

Air handlers can be located around the building to minimize the length of duct runs. In multistory office buildings they are located either on every floor serving that floor or on about every 16 floors serving 8 floors up and 8 floors down.

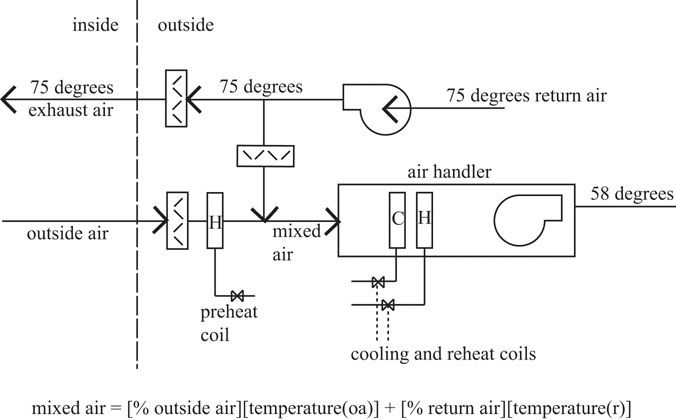

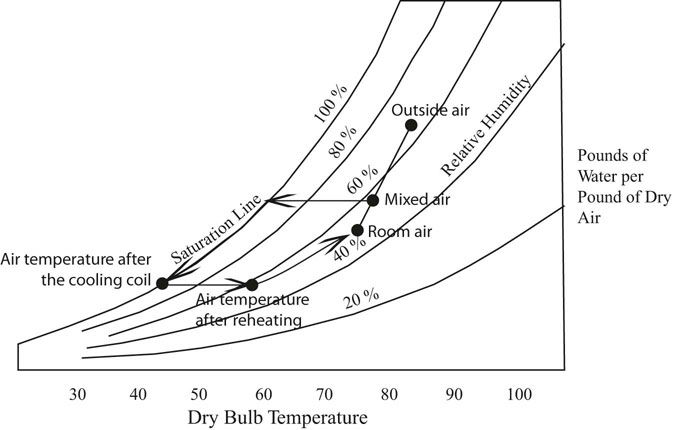

The functioning of an air handler needs to include return air drawn back by the return fan, a set of dampers to control the amount of exhaust air and the amount of fresh air, and the mixing of return air and fresh air. All commercial buildings are required to bring in outside air at a minimum of 17 cubic feet per minute per person. This air can be at or below freezing during the winter months so a preheat coil is necessary to ensure that freezing air does not reach the cooling coil and freeze the water in the coil. The fresh air is then mixed with a portion of the return air before being drawn into the air handler. The air handler first cools the air down. This results in saturated air at about 45 degrees. If this air was delivered into the rooms the result would be cool but very humid spaces. The reheat coil then heats the air up to about 58 degrees, which also lowers the relative humidity of the air to about 50 percent. This air is then delivered to the rooms needing cooling. The slope of the line on the psychrometric chart between the delivered air and the room air is determined by the ratio of sensible and latent load in the receiving rooms (Figure 23.3). A steep line represents a situation where there is more latent load than sensible load. The slope of the line shown on the chart represents a latent load of about 30 percent and a sensible load of about 70 percent.

FIGURE 23.2 The configuration of a typical air handler unit with its accompanying return fan and dampers to control exhaust air, recirculated air, and outside fresh air.

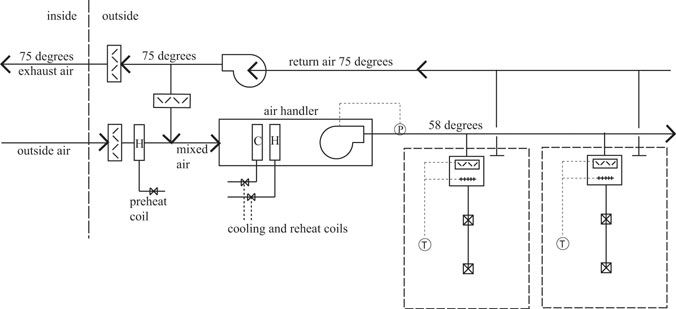

The simplest HVAC system is a single zone constant volume system (Figure 23.4). Air is delivered to the room at a constant volume flow rate. The temperature of the air is changed to respond to heating or cooling needs. This is a good system for large rooms like auditoriums.

Where a building has many spaces and multiple exterior orientations, the HVAC system needs to be able to respond to different needs for heating and or cooling in different rooms in the building. A variable air volume HVAC system is used in this case (Figure 23.5). The air handler delivers cool air into the supply duct system. At each room there is a variable air volume box that allows cool air into the rooms that need cooling. The temperature of the delivered air is set to meet this cooling load. In the zones where the cooling load is smaller, the variable air volume box reduces the amount of cool air delivered to the space, thus reducing the amount of delivered cooling. Where a room needs heating, the variable air volume box shuts air flow from the supply duct down to a minimum, usually about 25 percent of full flow. Then the air is heated with a hot water coil located downstream of the variable air volume control. This is called reheat.

FIGURE 23.3 A plot on a psychrometric chart of the temperature and humidity characteristics of the air as it flows through the mixing dampers and the air handler unit to distribution into the conditioned space.

FIGURE 23.4 A single zone constant volume HVAC system.

Since interior zones are in need of cooling all year long, a variable air volume HVAC system without reheat works well in these interior zones responding to modest variation in the amount of cooling necessary. Heating is not necessary. Exterior zones need reheat because they will need heating during colder months. Ideally each exterior orientation has its own variable air volume system so the delivered air can be set to the appropriate temperature for that exposure, thus minimizing the amount of reheat.

FIGURE 23.5 A variable air volume HVAC system.

Variable air volume HVAC systems save energy in two ways. First, they minimize reheating by lowering the volume of air delivered before reheating it. Second, since most of the time there are a large number of variable air volume boxes reducing the air flow to the spaces they serve, the pressure in the supply duct will increase. A pressure sensor tells the fan in the air handler to slow down, thus saving on electricity used to drive the fan.

Exterior zones can also be served by a four pipe induction system. In each exterior office there is a unit with a cooling coil and a heating coil large enough to do the heating or cooling of the office. Fresh air in the required amount is tempered in a central air handler and delivered at high velocity to the induction unit with its coils. The fresh air stream is blown across the coils inducing room air to go along for the ride. The coils do the heating and cooling.

Another system that is used in office buildings is a chilled beam system. In this case a large portion of the cooling needs of the office space is delivered by panels mounted on the ceiling that have chilled water cooling them down. The chilled beams provide radiant cooling as well as cooling air that passes near the chilled beam. The air delivered into the spaces needs to be carefully dehumidified so that condensation does not form on the chilled beams.

There are various systems to reduce the amount of energy that an HVAC system uses. They can be organized into categories: systems that save energy through the difference in temperature and humidity of the exhaust air and the outside air, systems that recapture and store heat that the chiller would normally exhaust to the environment, and systems that store cool in the form of chilled water or ice.

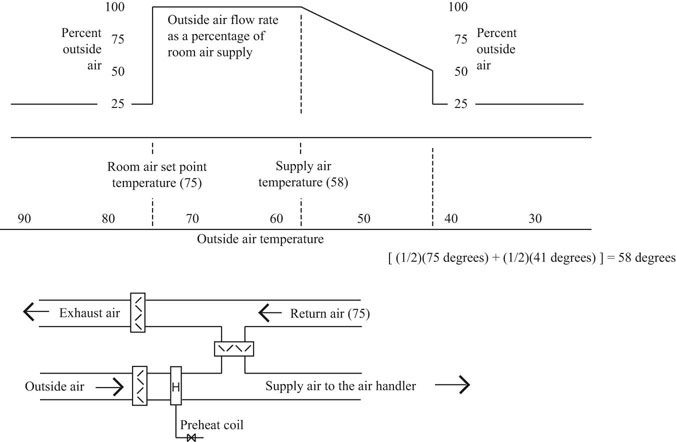

One of the most common energy saving systems is an economizer (Figure 23.6). An economizer takes advantage of the fact that when the outside air is cooler than the return air from the zones being served it requires less cooling to throw away 100 percent of the return air and bring in 100 percent fresh outside air. Consider the situation where it is 58 degrees outside. The design delivery temperature for the air handler is 58 degrees. The economizer will bring in 100 percent outside air at 58 degrees and the air handler will not have to cool the air since it is already at the appropriate temperature. As the temperature gets colder than the delivery temperature, the economizer will slowly shut down the amount of outside air to the minimum amount for fresh air. Actually it is not quite this simple since humidity is also involved in the control systems of economizer systems. When temperature and humidity are considered, the economizer is enthalpy controlled.

FIGURE 23.6 An air economizer system along with its operational temperature range.

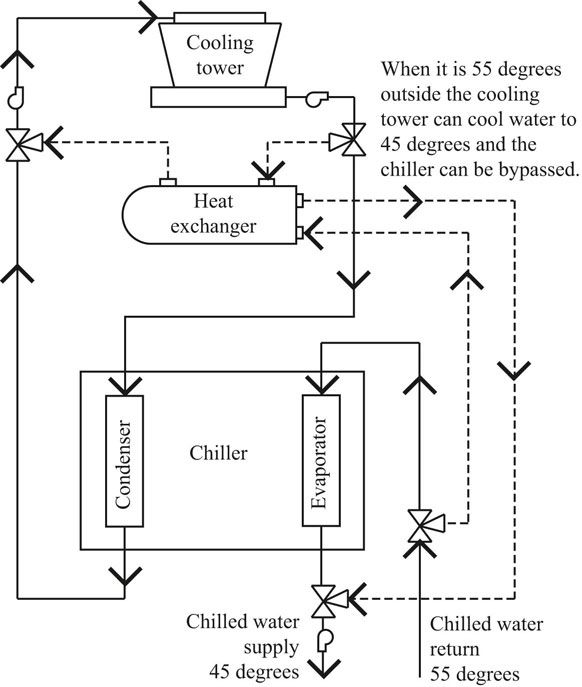

In the situation where it is not possible to have 100 percent exhaust and fresh air streams, it is possible to achieve a similar result with a system called free cooling (Figure 23.7). In this system the cooling tower is used to directly chill the chilled water when it is cold enough outside to do this. The chiller is bypassed and turned off.

A run around coil places a coil with an antifreeze liquid solution in the exhaust air stream and in the supply air stream (Figure 23.8). A pump moves the liquid between the coils. This recaptures heat in winter and cool in summer.

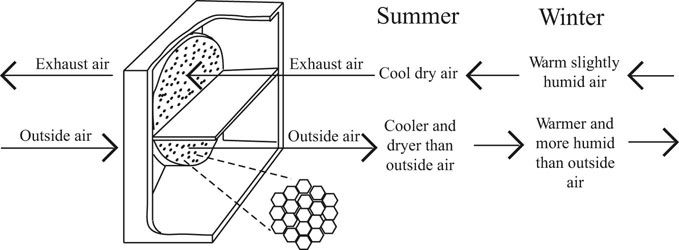

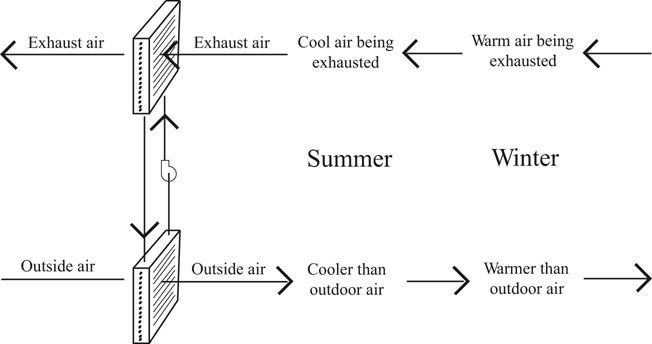

An energy transfer wheel is a honeycomb made up of a light weight material like aluminum and has a desiccant on the surface of the aluminum (Figure 23.9). The wheel turns between the exhaust air stream and the outside air stream. In the winter the aluminum recaptures heat and the desiccant recaptures humidity from the exhaust air stream. The heat and humidity are then put into the fresh outside air stream warming it and humidifying it. In summer the aluminum recaptures coolness and the desiccant is dried out by the low interior humidity. The coolness and lower humidity levels are then put into the fresh outside air stream being brought into the building.

FIGURE 23.7 A cooling side economizer system often called free cooling.

FIGURE 23.8 A run around coil system to recover heat or cold from the exhaust air and deliver it to the supply air.

FIGURE 23.9 An energy transfer wheel can capture both heat and humidity from the exhaust air and deliver it to the supply air.

FIGURE 23.10 A dual condenser chiller captures some of the heat that would be rejected to the cooling tower for use in the building.

The chiller takes heat out of the chilled water that is used to cool air in the air handlers. The chiller then exhausts the heat to the atmosphere through the cooling tower. A dual condenser chiller can capture some of the heat that is going to the cooling tower and store it as hot water to be used in other building conditioning systems (Figure 23.10).

The peak cooling needs of a building generally happen in the early afternoon, and the highest peak cooling happens in late summer. The electric utility companies have to deliver electricity on demand. There is no good way to store electricity. It is expensive for the utility companies to have standby electric generation capacity so they charge commercial customers for their energy use, and for their peak use. To reduce peak demand, a building’s chillers can be used at night to store chilled water or ice. There are two advantages: peak demand is lowered saving money, and the chillers run more efficiently because it is cooler at night than during the day, saving energy and money.