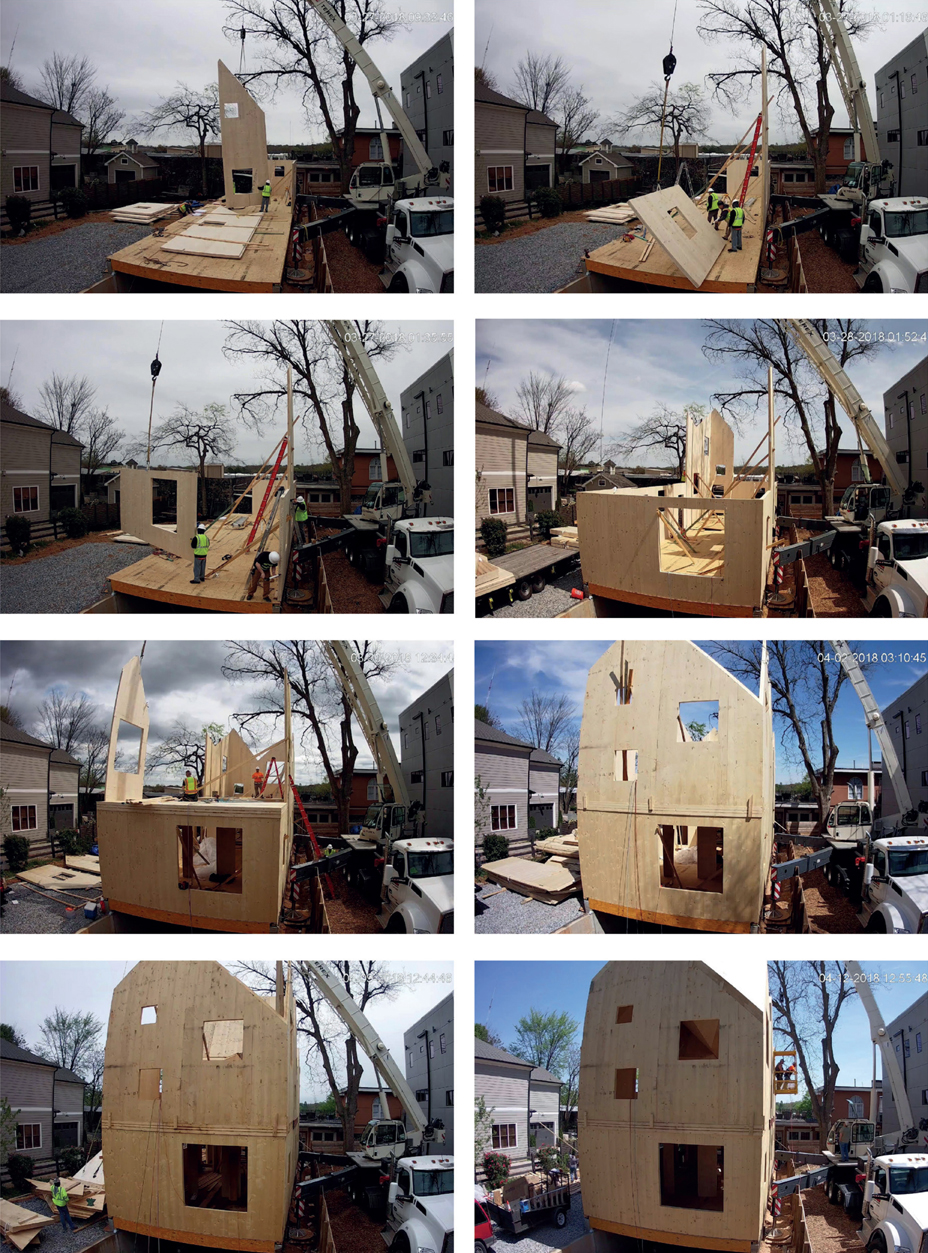

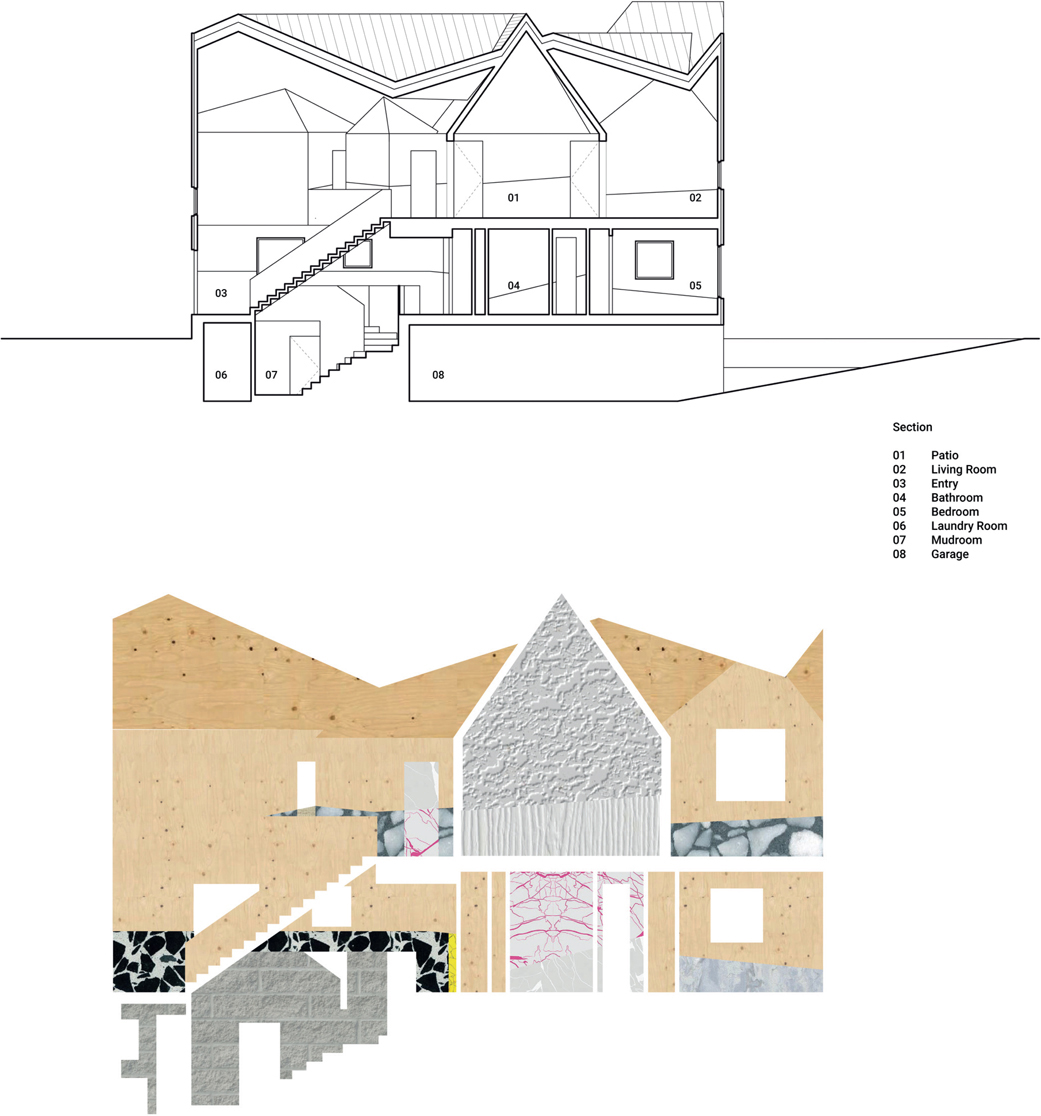

FIG 16.0 (chapter opener) Interior and exterior forms and volumes are defined throughout by CLT planes exploiting the structural and visual properties of large format panels. Areas of interest: Milestone US project; Roof form achieved by use of CLT panels; Combination of exposed panels with applied internal finishes. A dramatic external form encloses and defines soaring internal volumes to this new-build single-family dwelling house on a constrained urban plot in Atlanta, Georgia, USA. CLT panels form faceted, folded and long-spanning planes, exploiting the structural qualities of the two-way spanning panels with the joyful celebration of structure amplified by a contemporary and playful approach to applied surfaces and colour (See Figure 16.1). FIG 16.1 Haus Gables exterior. The structure is comprised of 87 unique individual panels up to 10.4m long utilising 3-ply panels for walls, 5-ply for the roof and 7-ply, up to 240mm thick, for the floor structure, all over a concrete basement plinth. Roof form and therefore the internal soffits were informed by extensive research into roof typologies of the American South. The architect also intended to challenge the notion of a traditional dwelling, typically formed from a wood frame of small section lumber and overclad with drywall throughout – the last thin layer of sheet material defining spaces and volumes. Instead the CLT panels form the character of different spaces as well as bearing load and enclosing volume. FIG 16.2 Long sections illustrating roof form, voids, level changes and faux finishes. CLT panels lend themselves well to roof structures. Without ties, the origami-like roof serves as a form of shell, a folded panel reminiscent of a card model built 1:1. As is typical for many mass timber projects, there were a number of different structural engineers involved over the project. Beyond initial investigations and concept development, another firm picked up the design development and then outsourced detailed timber calculations to another. A fourth company designed the slab connections specifically (a key element for most CLT structures as they interface with concrete plinths or slabs) and resolved specific local code approvals based on inputs from predecessors. FIG 16.3 Aerial view of roof form after completion of panel assembly. Interiors are defined by structural panels, the geometry creating soaring volumes expressing external form and by a range of faux finishes applied to lower surfaces. Finer materials are contrasted with the robust finish and texture of exposed panels. The wainscoting of applied finishes also conceals service chases to lower levels and creates opportunities for further expression of occupied spaces through the contrasting use of colour blocking. Timber is exposed to a greater extent in more intimate areas such as bedrooms or covered as required in wet areas and panels are also used to form stairs, balustrades and suspended elements. A number of suppliers were put off by the apparently complex form, but the architect digitally designed and nested each panel within larger ‘blanks’ (full panels representing the optimum size available since panels were FIG 16.4 Roof form reflected by underside of exposed panels. FIG 16.5 CLT panels act as a folded plate and bedroom beyond landing is hung from larger roof above. FIG 16.6 CLT wall and roof surfaces are exposed on the bedroom interior. to be shipped in containers from Europe). This demonstrated the most efficient cutting arrangements for pieces forming the irregular geometry. Working closely with an Austrian panel supplier enabled the design team to draw upon the manufacturer’s very extensive experience of milling and processing complex details, which proved invaluable in detailing, before checking (and rechecking) every connection detail. The construction process required careful planning and key to this was communication between various team members, including pre-empting difficulties by scenario planning. Following investigation of the only comparable precedent, a house in Seattle, Washington,1 the same specialist installer was recruited to help inform and guide the detailed design, preparation and assembly process. A key challenge was site logistics and providing a crane and staging area on a constricted narrow site, but panels were arranged so they could be craned from each of the 11 trailers delivered in order of assembly. A team of 4 workers installed all the panels over just 14 days before the build was handed over to the general contractor for completion. This was one of the earlier full CLT houses in the US and the use of such panels enabled a highly efficient resolution and stunning expression of the complex geometry. Lessons learnt can of course be applied to more straightforward forms. FIG 16.7 Volumes are defined throughout by exposed structural CLT panels and double height voids to living areas offer expansive internal views. FIG 16.8 Site works during assembly of pre-manufactured panels.

CASE STUDY

HAUS GABLES, ATLANTA, USA

Project name:

Haus Gables

Location (including local authority):

Atlanta, Georgia, USA

Sector/type:

Residential (single family house)

Year completed:

2019

Area of building (GIA):

204m2

Volume of CLT (m3):

Undisclosed

Overall construction cost (million):

Undisclosed

Total height of building:

10.1m

Client(s):

Volkan Alkanoglu & Jennifer Bonner

Architect:

Jennifer Bonner, MALL

Main contractor:

Principle Builders Group

QS:

Undisclosed

Structural engineers:

AKT II; Bensonwood; PEC Structural; Fire Tower

Timber engineer:

As structural

CLT contractor:

Terry Ducatt (installation specialist)

CLT manufacturer:

KLH Massivholz, via KLH USA

PROJECT SUMMARY

FORM

STRUCTURE

INTERIORS

PROCUREMENT AND SEQUENCING