NEIGHBOR NOISE HAS ALWAYS BEEN CONSIDERED a significant factor in the rating of satisfaction in new and refurbished dwellings. The control of sound within dwellings is therefore a statutory requirement in most countries and it is also included in most assessment methods used to determine sustainability. In most instances the statutory requirements are set as minimum target values rather than optimum insulation levels and as a result there can be conflict between end-user expectation and national or regional requirements. The target values adopted around the world look to provide reasonable levels of insulation in the hope that this will satisfy the majority of occupants. For this reason, designers and developers should be wary of using terms like “soundproof,” as even the best-performing walls and floor systems have the potential to allow for some transmission of sound.

12.2.1 Partitions between dwellings

Table 12.1 details the level of occupant satisfaction compared to the measureable sound insulation for partitions separating dwellings. Appendix C outlines a limited number of partition types for use in separating constructions.

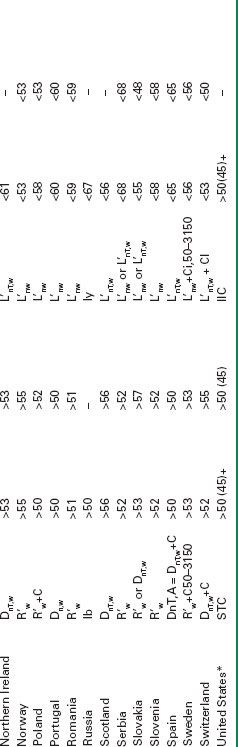

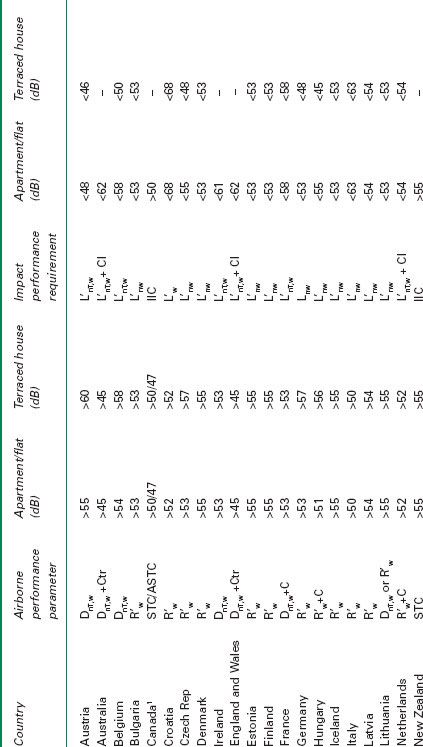

Controlling sound transmission is most important in adjoined dwellings and it is generally a requirement of building codes and regulations in many countries across the globe. Table 12.2 shows the expected performance levels required by different building regulations in some countries around the world.

Table 12.1 Perceived satisfaction levels of sound insulation for separating partitions (Smith et al., 2006)

Perceived rating | Airborne sound | Impact sound |

DnT,w (dB) | L’nT,w (dB) | |

A*Excellent | 62–64 | <47–49 |

A Very good | 59–61 | 50–52 |

B Quite good | 56–58 | 53–55 |

C Acceptable | 53–55 | 56–58 |

D Barely acceptable | 50–52 | 59–61 |

E Poor | 47–49 | 62–64 |

F Very poor | 44–46 | 65–67 |

G Intolerable | 41–43 | 68–70> |

12.2.2 Internal partitions

In addition to sound insulation between dwellings, it is considered good practice to ensure a minimum level of acoustic insulation for partitions within dwellings. Insulation levels of STC/Rw 40–43 dB should be seen as a minimum requirement for walls and floors within a house.

The use of single stud partitions with high-mass plasterboard linings (e.g., minimum 10 kg/m2) and the inclusion of a layer of mineral fiber quilt would provide a minimum specification to achieve this level.

12.2.3 Doors to apartments/flats

Doors to apartments/flats which open onto a common lobby or stairwell should be specified as having a minimum performance of STC/Rw 29 dB. Solid core timber doors are usually capable of achieving this level of insulation. It is also good practice to include compressible seals in these doors in order to reduce sound transmission.

THE FOLLOWING ADVICE OUTLINED in Figures 12.1 and 12.2 would hold true for any building design, but it is particularly relevant to the design of housing or rooms for residential purpose where the aim is to reduce the magnitude of noise being transmitted from one part of a building to another.

Table 12.2 Domestic sound insulation requirements around the world for new-build constructions (COST, 2013)

1 As per proposed changes 2013

*United States guidelines for federal housing; state guidelines may differ

+ First value is for laboratory test data; value shown in brackets for on-site testing

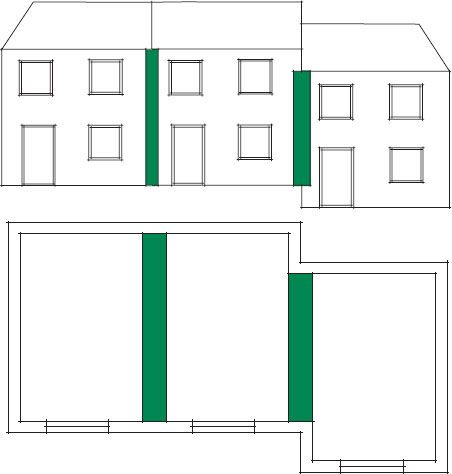

Steps and staggers between noise-sensitive buildings can help improve sound insulation by reducing the effective area of common wall.

Steps and staggers between noise-sensitive buildings can help improve sound insulation by reducing the effective area of common wall.

Minimum steps and staggers of 1 ft (30 cm) should be considered if included for acoustic performance reasons.

Minimum steps and staggers of 1 ft (30 cm) should be considered if included for acoustic performance reasons.

Steps and staggers of this size or greater can improve performance by up to 6 dB.

Steps and staggers of this size or greater can improve performance by up to 6 dB.

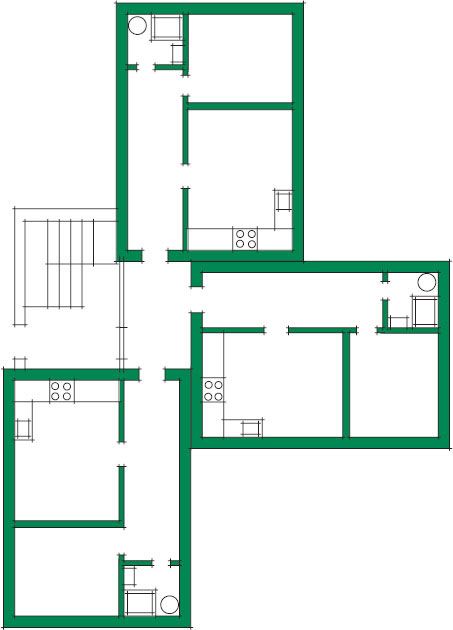

Stack rooms so that noise-sensitive spaces are above one another. Avoid placing kitchens above or below bedrooms.

Stack rooms so that noise-sensitive spaces are above one another. Avoid placing kitchens above or below bedrooms.

Cluster around a central stair well so that areas of common walls are limited in size.

Cluster around a central stair well so that areas of common walls are limited in size.

12.2 Avoiding sensitive adjacencies in multistory buildings

12.3 Handling of adjacent rooms

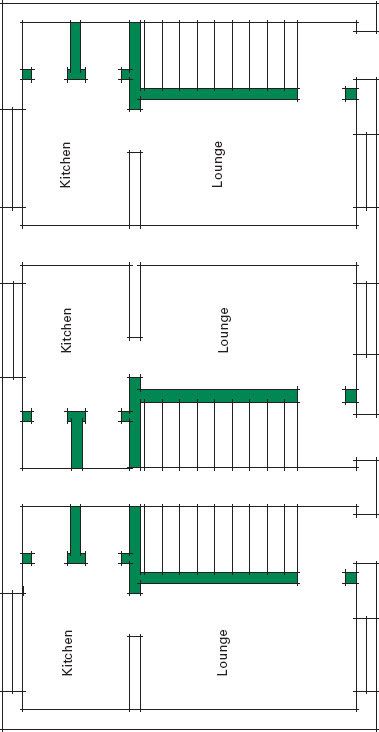

Design layouts so that noisy activities back on to less sensitive areas (e.g., kitchens to circulation).

Design layouts so that noisy activities back on to less sensitive areas (e.g., kitchens to circulation).

Situate noise-sensitive spaces such as bedrooms as far from other dwellings as possible.

Situate noise-sensitive spaces such as bedrooms as far from other dwellings as possible.

Place stairwells and lift shafts as remote from noise-sensitive areas as possible.

Place stairwells and lift shafts as remote from noise-sensitive areas as possible.

Noise from common circulation spaces can be further reduced by separating the stairwell from the entrance lobby to the dwellings on each floor with a glazed screen and door.

Noise from common circulation spaces can be further reduced by separating the stairwell from the entrance lobby to the dwellings on each floor with a glazed screen and door.

Advice specific to individual building types is given in other sections of Part II of the book, but for general layouts within dwellings Figure 12.3 offers some basic guidance.

Use stairwells, circulation, and cupboard space as buffer zones between noise-sensitive rooms such as lounges and bedrooms. Limiting direct adjacencies of noise-sensitive spaces is preferred.

Use stairwells, circulation, and cupboard space as buffer zones between noise-sensitive rooms such as lounges and bedrooms. Limiting direct adjacencies of noise-sensitive spaces is preferred.

Where adjacencies are unavoidable, place quiet rooms back-to-back and noisy rooms back-to-back (e.g., kitchen to kitchens, and lounges to lounges).

Where adjacencies are unavoidable, place quiet rooms back-to-back and noisy rooms back-to-back (e.g., kitchen to kitchens, and lounges to lounges).

12.4.1 Identifying good materials or products for reducing sound transmission

When selecting suitable acoustic lining systems to use on a floor or wall, such as bonded resilient coverings, floating floor treatments (batten, cradle, or deck overlay systems), or resilient bar lining systems, manufacturers should prove that their systems can meet minimum standards based on laboratory data.

In this instance, the ΔLw or ΔRw parameters are used. This is the level of improvement a system has achieved when tested on a base timber or concrete floor under laboratory conditions. Regardless of whether it is an impact (ΔLw) or airborne (ΔRw) result the Δ character means that the higher the value, the better the performance. The minimum requirement for each lining system is listed below:

Bonded resilient coverings on concrete floors – ΔLw 17 dB

Bonded resilient coverings on concrete floors – ΔLw 17 dB

Floating floor treatments on concrete floors – ΔRw 5 dB; ΔLw 22 dB

Floating floor treatments on concrete floors – ΔRw 5 dB; ΔLw 22 dB

Floating floor treatments on timber floors – ΔRw 17 dB; ΔRw+Ctr 13 dB; ΔLw 16 dB

Floating floor treatments on timber floors – ΔRw 17 dB; ΔRw+Ctr 13 dB; ΔLw 16 dB

Resilient ceiling bars on timber floors – ΔRw 16 dB; ΔRw+Ctr 14 dB; ΔLw 16 dB.

Resilient ceiling bars on timber floors – ΔRw 16 dB; ΔRw+Ctr 14 dB; ΔLw 16 dB.

12.4.2 Refurbishment and remedial treatments

Acoustically treating existing walls and floors is an incredibly complex task and would justify an entire book in itself. It is not uncommon to find that treatments that worked well on one development do not provide the same performance on other developments. This is primarily due to changes in existing detailing or variations in the integrity of the existing floor or wall. There are, however, some basic rules of thumb that can be applied:

Independent linings to walls or ceiling (e.g., self-supporting metal stud, quilt, and a plasterboard lining) should provide better levels of acoustic insulation than a lining system which is fixed back to the existing wall or floor.

Independent linings to walls or ceiling (e.g., self-supporting metal stud, quilt, and a plasterboard lining) should provide better levels of acoustic insulation than a lining system which is fixed back to the existing wall or floor.

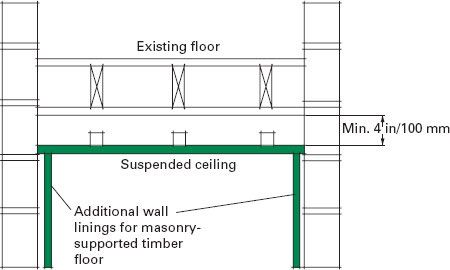

The deeper the cavity depth created by a wall or ceiling lining, the better it will perform. Minimum depths of 4 in (100 mm) are suggested.

The deeper the cavity depth created by a wall or ceiling lining, the better it will perform. Minimum depths of 4 in (100 mm) are suggested.

12.4 Section – remedial acoustic ceiling treatment of masonry-supported timber floors

Masonry-supported timber floors that are to be converted into separating floors between dwellings often suffer from flanking transmission problems, so it may be necessary to allow for the lining of load-bearing walls (e.g., metal lining frame, quilt, and plasterboard).

Masonry-supported timber floors that are to be converted into separating floors between dwellings often suffer from flanking transmission problems, so it may be necessary to allow for the lining of load-bearing walls (e.g., metal lining frame, quilt, and plasterboard).

Retaining original finishes can often be beneficial. Lath and plaster ceilings and existing ash deafening/pugging between joists on pre-1920s constructions provide significant acoustic benefit and should be retained where possible.

Retaining original finishes can often be beneficial. Lath and plaster ceilings and existing ash deafening/pugging between joists on pre-1920s constructions provide significant acoustic benefit and should be retained where possible.

12.4.3 Avoiding risk when detailing partitions for dwellings

The following outlines good practice in the design of separating walls and floors between dwellings:

Masonry wall constructions which incorporate twin leaf walls are preferable to single leaf constructions. Minimum cavity depths of 4 in (100 mm) between leaves are best, as is the use of very lightweight wall ties. Block work with higher densities tend to perform best.

Masonry wall constructions which incorporate twin leaf walls are preferable to single leaf constructions. Minimum cavity depths of 4 in (100 mm) between leaves are best, as is the use of very lightweight wall ties. Block work with higher densities tend to perform best.

Only where single leaf constructions include a metal or timber stud lining system with fiber insulation and plasterboard finishes can similar insulation levels be achievable.

Only where single leaf constructions include a metal or timber stud lining system with fiber insulation and plasterboard finishes can similar insulation levels be achievable.

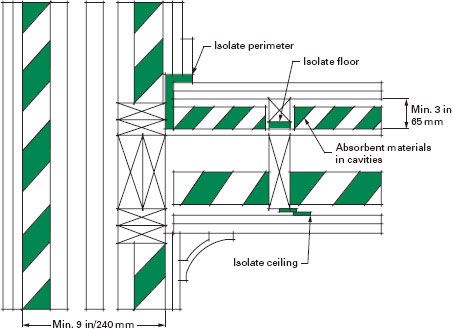

Twin independent timber or metal stud systems can be suitable for walls between dwellings, assuming each leaf is independent. Internal cavity depths of 9½ in (240 mm) are preferable. Double layers of plasterboard and fiber insulation within the cavity are required.

Twin independent timber or metal stud systems can be suitable for walls between dwellings, assuming each leaf is independent. Internal cavity depths of 9½ in (240 mm) are preferable. Double layers of plasterboard and fiber insulation within the cavity are required.

The use of fiber insulation within any wall cavity should include instructions for the material to be stapled or held in place, to avoid sagging during the lifetime of the wall.

The use of fiber insulation within any wall cavity should include instructions for the material to be stapled or held in place, to avoid sagging during the lifetime of the wall.

Cast in-situ concrete floors tend to require less detailing in order to avoid sound leakage paths. Where pre-cast slabs are used, the inclusion of a poured concrete topping or screed will ensure better performance levels.

Cast in-situ concrete floors tend to require less detailing in order to avoid sound leakage paths. Where pre-cast slabs are used, the inclusion of a poured concrete topping or screed will ensure better performance levels.

Concrete floor slabs are inherently good at controlling airborne sound but will require either an isolated floor treatment and/or a suspended or isolated ceiling treatment to control impact sound.

Concrete floor slabs are inherently good at controlling airborne sound but will require either an isolated floor treatment and/or a suspended or isolated ceiling treatment to control impact sound.

12.5 Section through floor/wall junction – good detailing practice for timber kit separating floors

Timber floor structures can provide good levels of insulation but are reliant on isolation layers being applied to both the top and bottom of the structural floor (e.g., floating floors and isolated or suspended ceiling systems).

Timber floor structures can provide good levels of insulation but are reliant on isolation layers being applied to both the top and bottom of the structural floor (e.g., floating floors and isolated or suspended ceiling systems).

Anything which bridges a cavity within a separating floor or wall can result in increased sound transmission. This includes mortar buildup within wall cavities, service runs through floors, failure to isolate floating floors at the perimeter, and continuous load-bearing elements such as walls and columns.

Anything which bridges a cavity within a separating floor or wall can result in increased sound transmission. This includes mortar buildup within wall cavities, service runs through floors, failure to isolate floating floors at the perimeter, and continuous load-bearing elements such as walls and columns.

Avoid locating elevator/lift shafts on walls that are common to living rooms or bedrooms.

Avoid locating elevator/lift shafts on walls that are common to living rooms or bedrooms.

Further reading

Building Research Establishment (BRE) and Construction Industry Research and Information Association (CIRIA) (1993) Sound control for homes. Englewood, CO: IHS/BRE Press.

COST (2013) Towards a common framework … in building acoustics throughout Europe. COST Action TU0901 final conference, Copenhagen, December 2013.

Robust Details (2013) Robust Details handbook. Milton Keynes: Robust Details Ltd.

Smith, S. et al. (2006) Housing and sound insulation, improving existing attached dwellings and designing for conversions. London: Arcamedia.