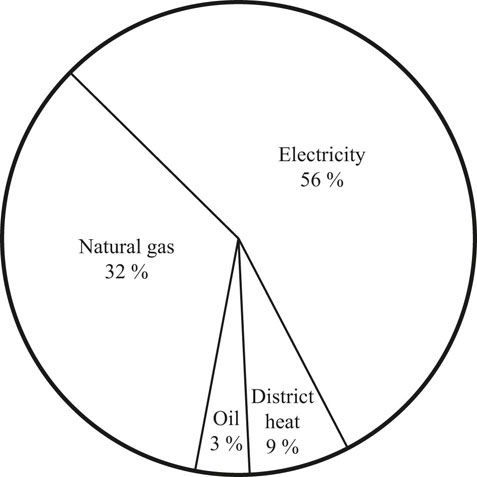

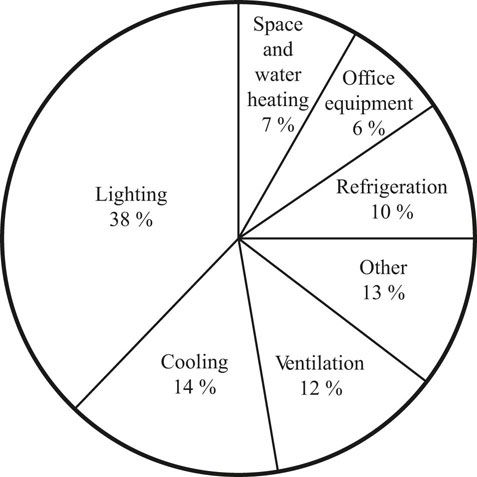

Most of the energy use of commercial buildings in the United States is electricity and natural gas. Electricity accounts for 56 percent of the energy use, and natural gas accounts for 32 percent (Figure 22.1). The natural gas is primarily used for heating, which suggests that increasing the thermal resistance of the building envelope can save significant energy. The electricity use in commercial buildings is 38 percent lighting, 14 percent cooling, and 12 percent ventilation (Figure 22.2). Lighting, being the largest usage of electricity in commercial buildings deserves considerable attention in any energy saving schemes.

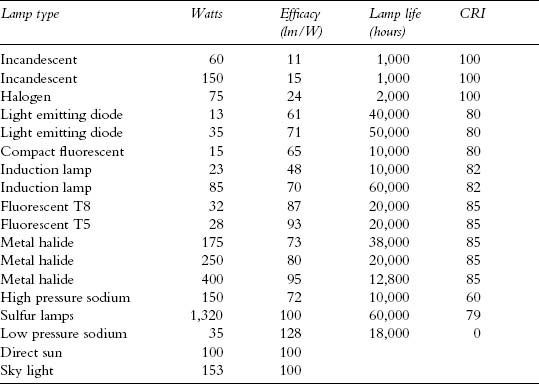

There are multiple dimensions involved in good energy efficient lighting. The efficacy of the light source is important. Efficacy is the lumens of light produced per watt of input energy (see Table 22.1). The quantity of light distributed onto working surfaces needs to be enough for the work that needs to be performed, but this quantity should be concentrated if possible only on the work area. The amount of light needed to walk around in lobbies and circulation spaces is lower than needed on work surfaces. When daylight is available to illuminate spaces, the electric lighting needs to be dimmed to save energy. When rooms, such as conference rooms, are not always occupied, there should be occupancy sensors to automatically turn off the lights.

Commercial buildings are primarily illuminated with linear fluorescent lamps. Newer fluorescent lamps are thinner, five eighths of an inch in diameter, than the traditional inch and a half diameter fluorescent lamps. Fluorescent lamps produce light by running an electrical current through a gas with mercury vapor in it. When electrons hit the mercury atoms the outer valence electrons of the mercury atoms are pushed to a higher level. When they fall back to their standard level they give off a limited multiline spectrum of light. This light is barely visible. The mercury spectrum is transformed to a useful spectrum of visible light with phosphors on the inside surface of the fluorescent lamp. Current phosphors provide a spectral mix of red, green, and blue light, which mixes together to produce white light with good color rendering, and high efficacy.

FIGURE 22.1 Commercial building energy use by source for the United States.

Source: United States Energy Administration, Annual Energy Review 2011. www.eia.gov/are.

FIGURE 22.2 Commercial building electricity use by function in the United States.

Source: United States Energy Administration, Annual Energy Review 2011. www.eia.gov/are.

TABLE 22.1 Lamp wattage, efficacy, life, and color rendering index (CRI).

Source: United States Department of Energy, U.S. Lighting Market Characterization, Volume II: Energy Efficient Lighting Technology Options.

The quality of the light distribution from light fixtures is a very important feature of energy efficient lighting and indoor environmental quality. Overhead lighting can create two types of glare, which can reduce the effectiveness of the light. Direct glare comes from bright lamps in one’s field of view. This is fairly easy to control with lenses or baffles that block the direct view of the bright lamp within the light fixture. Reflected glare is more difficult to control. Reflected glare manifests itself as a reflection of the bright lamp on top of the work product that a person is trying to see. One solution to this problem is to have light come from a large diffuse source, but this can be energy inefficient. A compromise solution seen often in energy efficient office lighting is direct indirect light fixtures hung on pendants 8 to 12 inches below a white ceiling. Half the light reflects off the ceiling and half the light is directed down. This produces a good mix of direct and diffuse light. The quantity of light is generally set at 30 foot-candles, which is enough light to read a book and plenty of light to move around in an office. Where more illumination may be needed, task lighting can be built into the furniture system. Ideally the task lighting has the same color temperature and efficacy as the general illumination.

Lobbies and circulation spaces often have down lights recessed into the ceiling. The amount of illumination needed to navigate circulation spaces can be as low as 10 to 20 foot-candles. These down lights are primarily compact fluorescents which have significantly higher efficacies than the incandescent lamps that they replaced. A 15 watt compact fluorescent lamp can replace a 60 watt incandescent lamp, and a 25 watt compact fluorescent lamp can replace a 100 watt incandescent lamp. Light emitting diodes (LEDs) have slightly better efficacies than compact fluorescent lamps but are more expensive.

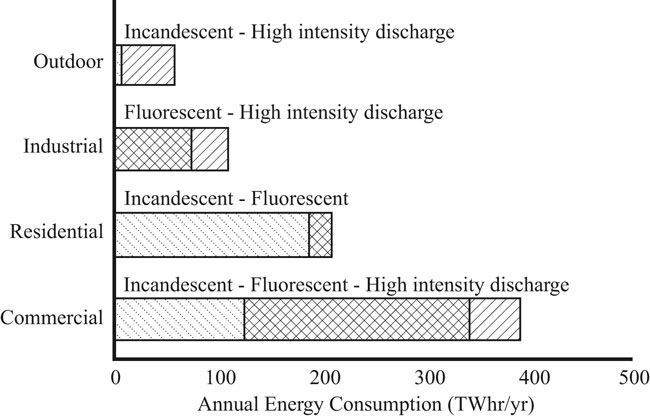

In retail stores the lighting is a mix of fluorescent and metal halide. Metal halide lamps are a high pressure gas with a mix of metals in the gas including mercury that, when an electric current is sent through the gas, give off a wide and diverse spectrum of light. Metal halide lamps provide similar, and at high voltages higher efficacies than fluorescent light. The multiline wide spectrum of metal halide lamps produces a kind of sparkle along with good color rendering. Metal halide, along with mercury and sodium lamps, are collectively called high intensity discharge (HID) lamps because of the high pressure of the gas in the lamp. Fluorescent lamps have very low gas pressure.

All gas discharge lamps require a ballast to provide a surge of current to start the lamp and then to control the current flow through the lamp during use. Electronic ballasts consume ten to twenty percent of the electricity sent to the lamp. After a power failure, high intensity discharge lamps require from 3 to 20 minutes to restart. Fluorescent lamps restart right away (Hong, Conroy and Scholand 2005, 45–60). Retail stores also use spotlights to illuminate merchandise in order to draw our attention to what they want us to buy. These spotlights are often incandescent lamps because incandescent lamps produce light from a relatively small glowing filament, which can be focused into a beam of light. Gas discharge lamps do not focus well.

FIGURE 22.3 Lamp types used and annual energy consumption in outdoor, industrial, residential, and commercial buildings.

Source: United States Department of Energy, U.S. Lighting Market Characterization, Volume II: Energy Efficient Lighting Technology Options.

There are rooms that are not always occupied, such as conference rooms, break rooms, and bathrooms. These spaces should have motion or infrared detectors that automatically turn off the light in the room when there is no one using the room. Buildings do not need light; people need light.

LEDs are becoming more efficient and are penetrating many lighting markets. Initially, LED lamps were comparable in efficacy to incandescent halogen lamps. Currently, LED lamps are comparable to compact fluorescent lamps. As efficacy increases, LED lamps can provide a major reduction in lighting energy use. There is also the added benefit that LED lamps have no current surge as they start, and have no delayed restrike time after a power interruption. Gas discharge lamps, fluorescent and high intensity discharge lamps like metal halides, need a current surge to strike the electric arc through the gas in the lamp. LED lamps dim much easier than gas discharge lamps, and the long lifetime of LED lamps can reduce the waste stream. Another advantage is the ability to produce LED lamps free of ultra violet (UV) and infrared (IR) energy. LED lamps will most likely replace incandescent lamps before making inroads into the fluorescent and high intensity discharge markets.

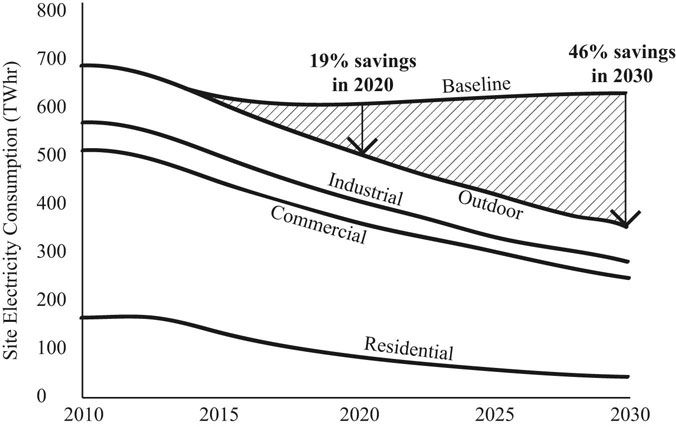

In 2001 lighting in the United States used 8.3 quads of electrical energy. Of this, 3.5 quads were incandescent lamps, 3.4 quads were fluorescent, and 1.4 quads were high intensity discharge. If white LED lamps can approach 160 lumens per watt and can penetrate 20 percent of the market, there is a potential savings of 1.1 quads. That would be a 13 percent reduction in electricity use for lighting (Hong et al. 2005, 92–98). The U.S. Department of Energy Solid State Lighting Program reports that by 2010 LEDs will be able to reduce lighting electrical needs by 19 percent, and by 2030 the reduction will be 46 percent.

FIGURE 22.4 Potential electricity savings from the further development and use of light emitting diodes.

Source: United States Department of Energy, Solid State Lighting Program.

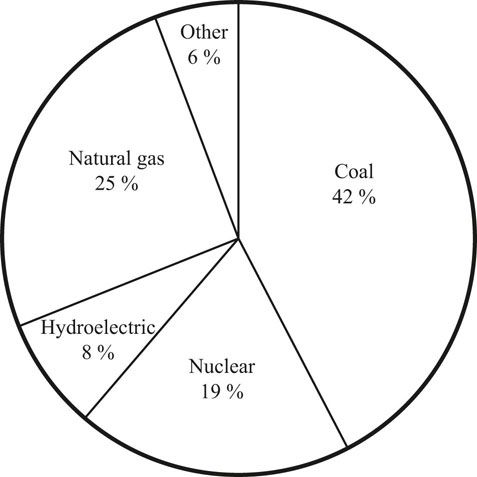

FIGURE 22.5 Electricity generation by fuel type in the United States.

Source: United States Energy Administration, Annual Energy Review 2011. www.eia.gov/are.

Since coal, the energy source that creates the most carbon dioxide per quantity of energy, produces 42 percent of electrical energy in the United States (Figure 22.5), any reduction in lighting energy use has a magnified effect on decreasing global warming.