The majority of the work environment is served by mechanical HVAC systems. These systems are designed to provide a comfortable temperature and humidity range throughout the year. They are also designed to bring in fresh outside air. Fresh air is drawn in and mixed with return air. An equal amount of air is exhausted to the outside. If the fresh outside air is not sufficient, carbon dioxide will accumulate in the building. Carbon dioxide is an indicator for indoor pollutants since it is directly related to the number of people in the building. If carbon dioxide levels are too high there is not enough ventilation air. Sources of indoor air pollution include biological organisms, outgasing from building materials and furnishings, outgasing from cleaning materials, ozone from copy machines, and pesticides. Control of indoor pollutants is two pronged. First, it is important to control and or eliminate the pollutants. Second, it is important to have enough fresh outside air to dilute the remaining pollutants. It is also important to have local exhaust from problem areas like copy machine rooms, areas where solvents are used, and bathrooms (EPA 1990, 1–2).

In 1984, the World Health Organization reported that up to 30 percent of buildings were the subject of complaints about indoor air quality. The problem was most often the result of poor maintenance and operation of the buildings. Sick building syndrome (SBS) is the situation where occupants experience discomfort and health issues related to time spent in a building. People report headaches, fatigue, dizziness, nausea, and eye, nose, or throat irritation. The symptoms are relieved when not in the building, but the cause of the symptoms is not known and usually very hard to pin down. The solution is usually to take a careful look at indoor air pollutants and to increase outside air ventilation rates. Indoor pollutant sources can be chemical, volatile organic compounds (VOCs) that come from almost everything inside a building. Indoor pollutants can also come from biological sources like mold, pollen, and bacteria. Another source of indoor air contamination is chemical or biological contaminants coming in with the fresh air being drawn into the building. This includes vehicle exhaust, and building exhausts as a result of badly located fresh air intakes. Building related illness (BRI) is where there is a specific cause for cough, fever, chills, and muscle aches. An example of BRI is Legionnaires’ Disease, which is caused by a bacterium that grows in poorly treated cooling tower water. The aspirated water from the cooling tower then finds its way into the building through poorly located outside air intakes (EPA 1991, 1–2).

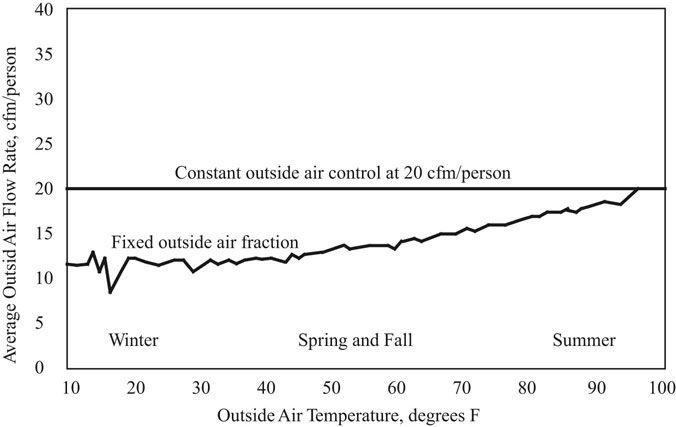

In a commercial building there are many different thermal zones. The dominant HVAC system responding to this multiple thermal zone problem is the variable air volume system (VAV). A VAV system supplies cool air through a supply duct. The temperature of the cool air is set to handle the largest cooling problem in the building. Other zones that do not need as much cooling reduce the amount of cool air entering the zone through a VAV box. If a zone needs heating, first the amount of cool air is reduced; then the air is reheated to provide the needed heat. As the air flow to individual zones is reduced, a pressure sensor in the supply duct tells the supply fan to reduce its air flow rate. As a result of this control scheme, most of the time the VAV system is operating at less than the design air flow rate. If the fresh air damper system is fixed to provide the proper amount of fresh air at the design air flow condition, most of the time there will not be enough fresh air entering the building. The difference between the design and actual amounts of fresh air gets larger as the weather gets colder (EPA 2000, 7).

FIGURE 24.1 Fresh outside air quantities supplied by a variable air volume HVAC system with constant (adjustable) outside air control compared to systems with fixed (unable to adjust) outside air control.

Source: EPA 2000.

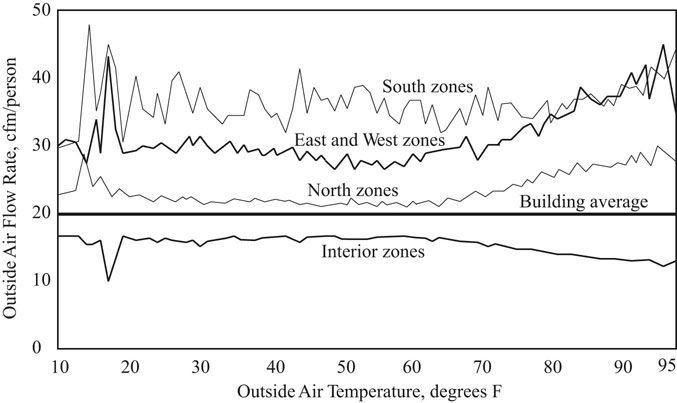

Buildings have interior and exterior zones. Interior zones are surrounded by conditioned space and therefore have no heat losses; thus an interior zone is a cooling all year long zone driven by the internal heat of people, lights, and equipment. The exterior zones on the east, south, and west can have large cooling loads as the sun moves through the sky. The north zone is more stable in its thermal needs. The exterior zones also have heating needs in cold weather. On average, the air flow in a building is about 1 cfm per square foot of building. The interior zone with its less demanding thermal requirement only needs about 0.5 cfm per square foot. The north zone needs about 1 cfm per square foot, and the east, south, and west zones need about 2 cfm per square foot. If there is one large VAV system supplying all these zones, the interior zone does not get its fair share of the 20 cfm per square foot that the air handling system is bringing in, and the east, south, and west zones get way more than their fair share of the fresh air (EPA 2000, 11). The solution to this problem is to have a separate VAV system for the interior zones, and ideally separate VAV or induction systems for each of the exterior zones. All the zones will then receive their fair share of the fresh outside air.

An economizer system compares the outside air temperature and humidity to the return air temperature. When the outside air is cooler than the return air temperature and not too humid, the economizer brings in up to 100 percent outside air and exhausts up to 100 percent of return air. As the outside air drops below the supply air temperature the economizer slowly adjusts the percentage of outside air down to the 20 cfm per person rate. During the time the economizer is in operation there is less to no need to cool the supply air. This saves energy. Also, while the economizer is operating, the amount of fresh outside air entering the building is vastly increased, which improves indoor air quality (EPA 2000, 8).

ASHRAE Standard 66–1999 calls for 15 cfm per person for education and auditorium occupancies. The high occupancy capacity of these venues results in a large outside air flow rate. This can make it difficult to control humidity when the outside air is warm and humid. An answer to this problem and to the energy use caused by large amounts of outside air is to install an energy recovery system that transfers both latent and sensible heat from the exhaust air to the outside air taken into the building (EPA 2000, 9–10).

Building designers and operators are always looking for ways to reduce energy use. Some of the methods used do not hurt indoor air quality and some can even improve indoor air quality. In general the energy savings schemes that are compatible with indoor air quality do not reduce the fresh outdoor air flow rate. Increasing the thermal resistance of the building shell, reducing lighting energy use and improving the efficiency of HVAC equipment does not affect indoor air quality. An economizer, and night pre-cooling, both bring in more fresh outside air than the required minimum amount and thus improve indoor air quality. Carbon dioxide controlled fresh air ventilation improves indoor air quality by insuring the proper amount of fresh air at all times. Reducing HVAC operating hours, reducing outside air ventilation rates, and using a fixed outside air flow rate with a VAV system will lower indoor air quality by reducing the fresh air flow rate below necessary levels (EPA 2000, 33–34).

FIGURE 24.2 Fresh outside air quantities supplied by a VAV HVAC system to exterior and interior zones of a building.

Source: EPA 2000.